Setting up a router table is a serious task, and following the schematics down to the detail is crucial, especially if you have never set up a table saw or a router table before. But what if the plans don’t mention the type of wood to use as your work surface? I had the same problem when I started out. Twenty years later, I have worked with multiple router tables and I can definitely give a detailed answer on whether is MDF or plywood best for router table.

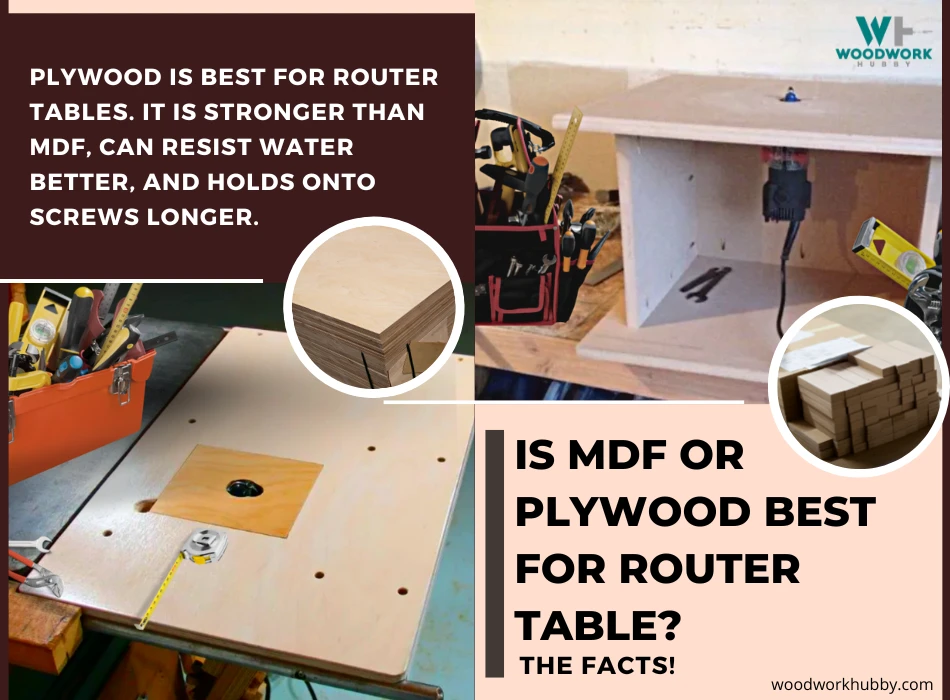

Plywood is best for router tables that are 3/4″ (19mm) thick or thicker. Plywood is stronger than MDF, can resist water better, and holds onto screws longer. MDF, on the other hand, doesn’t cost as much and is thick enough by default.

In this article, we will compare MDF and plywood as router tables’ work surfaces, so you will know the pros and cons of using each as a router table’s work surface. Among other things, you will discover the contexts in which MDF is superior and ones where plywood is. We will also go over which one you should use, depending on your situation. By the end, you’ll be confident about your choice.

MDF for Router Table: A Brief Overview

Medium Density Fiberboard is a wood board built as an amalgamation of wood fiber and adhesives. It is similar to plywood in that it passes as wood to the layperson but is not made of solid, homogenous wood.

The video shows making a DIY router table.

It is often used in high-use, low-maintenance surfaces that need to be relatively cheap and sturdy. Its medium density lends it medium-level strength, which is okay for a router table working surface. In fact, it is the default for most schematics.

MDF Router Table: The Pros

The advantages of router table surfaces made from MDF are plenty, which is why it is the default work surface choice for most router table plans. However, the sturdiness and durability advantages also translate to plywood, so they’re not very relevant in this case.

Here, the pros are mainly cost-related because MDF is cheaper than plywood. Let’s look at them individually.

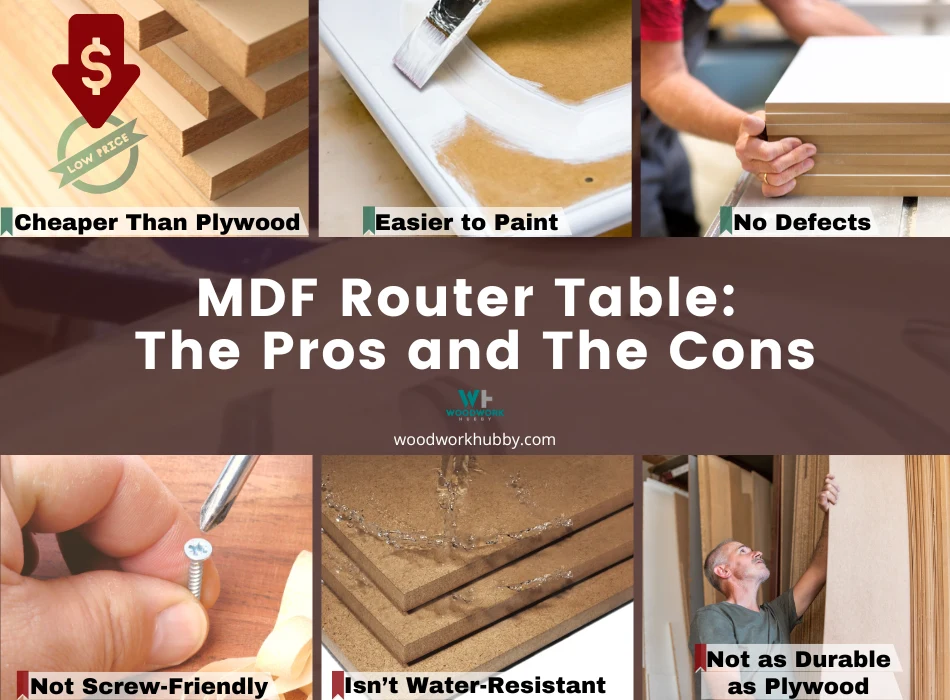

MDF Is Cheaper Than Plywood

MDF boards of 1-inch thickness are cheaper than plywood boards of similar thickness. For a fixed budget, you can get thicker MDF than plywood. And generally, the thicker a router table surface is, the better it is. This makes MDF boards more economical for a set level of thickness.

MDF Boards Are Easier to Paint

Plywood can be painted, too, but the MDF grain is easier to paint. Router tables don’t have to be painted, but if you prefer to make your workspace more aesthetically pleasing, then you might want to paint the router table. And in that case, the MDF surface will be easier to cover.

MDF Has No Defects

Plywood can have multiple defects, like delamination, poor plainness, and weak bonding. It is harder for MDF with weak bonding to pass quality control and make it to the market because the board will fall apart without proper adhesion. The MDF surface is straight, which makes for a perfect router table.

MDF Router Table: The Cons

While MDF is often cited in schematics for router tables, many advanced woodworkers have shied away from it. When it comes to router tables, MDF is definitely thick enough. But as I’ve learned from expensive errors, thickness is not all there is to a work surface.

Here are the drawbacks of an MDF router table compared to plywood.

Not Screw-Friendly

While the MDF surface can support a router table, it doesn’t sit well with screws and nails. To build a table, you need to hold a surface in place. If you do so with a screw or a nail, the wood fibers stacked randomly in the MDF can start dispersing.

Don’t confuse this with the table falling apart instantly. The screw holes just start to get larger over time. In contrast, it is really hard to get into plywood with a screw. But once you jam a screw or a nail in it, it tends to stay in place.

It Isn’t Water-Resistant

Another reason MDF is relatively suboptimal for a router table is that it doesn’t stand up to water very well. While plywood isn’t water-proof either, it resists water better than MDF. The higher surface area of wood fibers in a Medium-Density Fiber Board makes it easier for the board to soak up the fiber. In contrast, plywood has an easier time resisting water, especially because of its lamination but also because it is stacked perpendicularly.

The video shows an explanation of whether you can make MDF waterproof.

Not as Durable as Plywood

Finally, you have to consider the greatest drawback of router tables made with an MDF work surface: their comparative lack of strength. While MDF is thicker than plywood, plywood worktables of equal thickness are stronger than MDF. I used to find an MDF work surface once every 18 or so projects.

But as I started working on more advanced projects, one in every five projects required a sturdier router table. So the MDF router table’s suitability ultimately depends on your needs. If you’re a beginner woodworker or a hobbyist, you can start with an MDF work surface and graduate to plywood and, ultimately, hardwood, which I use most of the time.

You should use MDF for your router table if:

- You’re on a tight budget – an MDF table top will cost less.

- Work on low-to-medium-tier projects – MDF is strong enough to handle intermediate projects.

Plywood: A Brief Overview

Just like MDF, plywood is not solid natural wood lumber. However, unlike plywood, it isn’t a mashup of random wood fibers. Plywood has longer wood fibers that are placed and stacked perpendicularly. You might have noticed the world ply used in toilet rolls as well. It refers to layers, and plywood consists of multiple layers of thin wood fibers.

These are stacked together with a strong resin adhesive, which makes plywood harder than most softwoods. However, the cost of thickening the plywood is higher because the fibers cannot be placed at an angle to make the boards thicker with ease. The number of plys’s in the sheet has to be raised.

The video shows the building simple, strong, and cheap router table.

Plywood for Router Table: The Pros

Plywood is the ultimate non-hardwood choice for a router table. It has many desirable qualities that make it stand out against MDF.

This section explores the ways in which plywood is better than a router table.

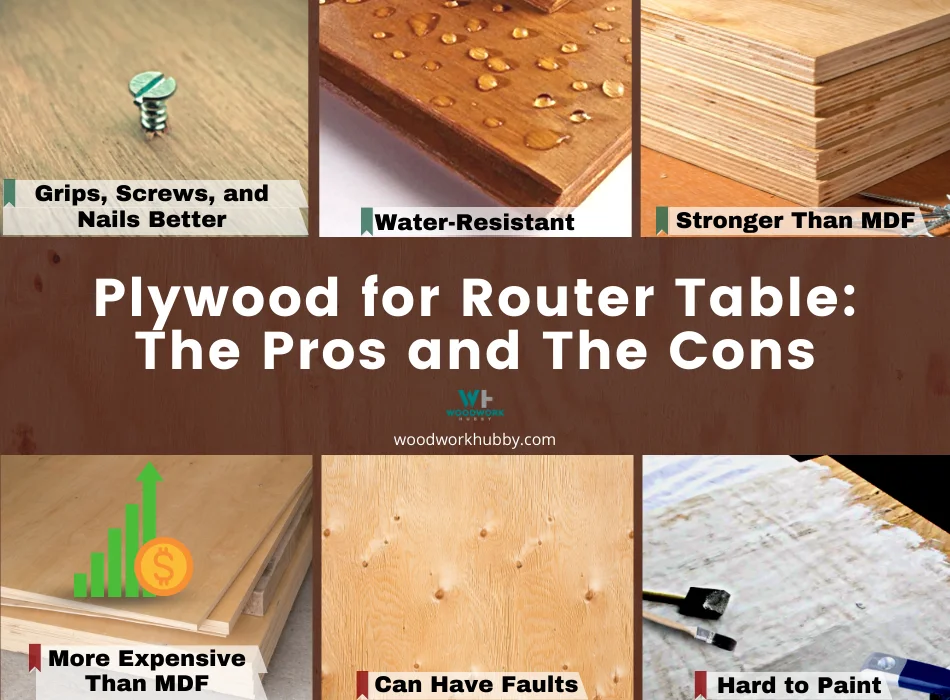

Plywood Is Stronger Than MDF (Of Equal Thickness)

The most crucial difference between plywood and MDF is that plywood is much stronger than MDF. Medium Density Fiberboards contain shorter fibers that are assembled more randomly. The fibers in plywood are stacked perpendicularly in plain layers.

The adhesives used in plywood are much stronger as well. Therefore, it makes sense to use plywood for a router table that is supposed to see heavier routing action. In my opinion, it is the perfect choice for an intermediate woodworker.

I have tested and proven whether OSB Or Plywood is the Best To Build Your Deer Blind? Check it!

Plywood Is More Water-resistant

Plywood is laminated, and its fibers are not as free to get water lodged between them. As a result, plywood is more water-resistant than MDF. In fact, plywood’s water resistance confuses novices into believing that plywood is water-proof.

That it is not. However, it can withstand an occasional spill much better than an MDF work surface. It is also laminated, preventing water from coming into contact with the comparatively vulnerable core.

Plywood Grips, Screws, and Nails Better

There’s also the matter of plywood’s internal adhesion. MDF’s fiber adhesion is strong but not nearly as strong as plywood. Generally, this affects the material’s ability to withstand weight and impact.

However, in the context of a router table, the internal adhesion also deals with screws and nails. With tough internal cohesion, the plywood core can take relatively better nails and screws. In contrast, fiberboard starts shedding fibers around the screw hole.

Plywood for Router Table: The Cons

While plywood is the prime candidate for intermediate and advanced router table use, it is not perfect in all aspects. It falls behind MDF in a few ways.

Let’s go over those in this section.

Plywood Is More Expensive Than MDF (Of Equivalent Thickness)

If you get the plywood and MDF for the exact same price, the plywood will be thinner and less durable than the MDF. But since we’re comparing equivalent thickness, plywood comes out stronger. Still, it is far from the most economical choice. That’s why beginner woodworkers should avoid jumping directly onto a plywood router table.

I always wonder how strong MDF is and what its limits are. Here is my detailed answer!

It Can Have Faults

While not every plywood sheet is faulty, plywood generally tends to have faults more often than MDF. C-grade plywood even has knots. For a router table, you need the work surface to be flawless. This increases the selection quality burden on you.

After all, you need to look at individual sheets and find the best one. This is still safer than buying stacks of plywood lumber, not knowing how straight the sheets inside are.

It Is Hard to Paint

This is a technical drawback that I feel is very nitpicky. Still, it is valid for some people. If you want to paint the router table work surface, it should be hardwood or even MDF. Plywood doesn’t take well to painting, and even when it does, the appearance feels off. I never painted my plywood tables, so I didn’t find this “drawback” limiting.

You should use plywood for your router table if:

- You live in a humid region – Moisture can accelerate how fast MDF falls apart. This doesn’t happen with plywood.

- You create heavy-duty projects – Plywood is sturdier than MDF. If the projects require further strength, consider a hardwood tabletop.

- You can afford to spend more money – Plywood is the stronger and the more expensive option of the two.

MDF vs. Plywood Router Table

A plywood router table is more robust than an MDF router table of equal thickness. Plywood also resists water spills better. An MDF router table is cheaper, which makes it an easier choice for beginner-to-intermediate woodworkers.

Is MDF Good for Router Table?

MDF is good enough for a router table used for small-scale and medium-scale projects. For extended use, plywood or even a hardwood router table might be needed. MDF will work well for a router table until the fibers start to deteriorate.

MDF is perfectly flat, which makes it an excellent work surface. But if the region you’re in is humid, the same tabletop can start falling apart after a year or two.

Be sure to check out my article: How Much Does MDF Weigh? Sheet Weights + custom calculator for you to use for free!

Is MDF Flatter Than Plywood?

MDF is flatter than plywood and has no grain. This makes it ideal for router tables and work benches. However, MDF’s durability keeps it from becoming the best choice for router tables and workbenches.

While flatness matters, strength matters even more. Still, plywood selection requires more expertise. It is easier to end up with faulty plywood while every MDF board is perfectly flat.

Is MDF Suitable for Tabletop?

MDF is perfect for table tops because it is completely flat and quite sturdy. However, when the table top is a work surface and power tools are used around it, MDF’s limitations must be considered. MDF is great for shop tables on which you work with hand tools.

It also works for regular household furniture. In fact, it is far better to use MDF for a household table than for a work table. It is designed for interior applications, which can be stretched to router tables but doesn’t seem to be among the manufacturer’s initial intentions.

With my 25 yrs experience with MDF, these are my findings If MDF Can Be Used Outside?

How Thick Should My Router Table Top Be?

Your router table top should be 1-inch thick. You should err on the side of having a thicker table top than having one that falls short of one inch. You have to account for sagging, so you cannot have a thin router table top.

After thickness, you need to consider the table’s flatness and straightness. It is critical not to end up with even a slightly leaning work surface. That can introduce a repetitive degree of error into your projects.

Final Thoughts

MDF is better for your budget than it is for a router table. Still, it works as a work surface for over 90% of the projects that require a router table. Plywood is comparatively more expensive, but a 1-inch router table top made from plywood is perfect for your router table.

-

What Is Cedar Wood Used For? (Why I Stopped Using It On Some Projects)

Cedar is one of my favorite wood types because I am tasked with perpetually protecting some of my passion projects. It is one of the most resilient woods out there, and I often find myself wishing that all woods were like Cedar because I cannot really use it for all projects. Cedar wood is used…

-

12 Beginner Wood Carving Projects Anyone Can Carve

Beginner Wood Carving As a woodworker, I believe woodcarving is one of the simplest forms of woodwork anyone could get involved in. If you start out with the most basic projects first, you can quickly develop the skills and the enjoyment to continue the hobby. I find I get a great sense of achievement from…

-

9 Essential Tips For Screwing Into MDF

MDF seems to be the one thing that scares most people whenever they need to screw into its edge. I have been a cabinetmaker for the last 20 years and screwing MDF together is something we did every day.All of the apprentices would be always asking how to screw into the edges of MDF without…

-

Maximizing Savings with Bulk Purchase of Wooden Cutting Boards for Your Restaurant

Running a successful restaurant business requires a delicate balance between offering top-notch culinary experiences and managing operational costs. One often overlooked but significant way to save money is by purchasing wooden cutting boards in bulk for your staff. These humble yet essential tools are the unsung heroes of any kitchen, and opting for cost-effective options…

-

Top 5 Best Portable Table Saw For Fine Woodworking

Are you struggling to find the perfect portable table saw for your fine woodworking projects? I know exactly how daunting that can be, having faced the same hurdle once upon a time. After many years of working as a contractor, I have used many table saws and so I decided to identify the best portable…

-

How To Remove Sticky Residue From Wood Table Top (It Works)

I totally get it. That unsightly sticky residue on your beautiful wooden table top just isn’t fun, is it? But how to remove sticky residue from wood table top without causing damage? After much research and plenty of experiments — some successful, others not so much — I’ve compiled quite a variety of methods to…

6 responses to “Is MDF Or Plywood Best For Router Table? The Facts!”

[…] from my experience where the MDF top is used in 7 out of every 10 projects. But when it comes to router tables and fixed power tools, as a table saw, I prefer using a sturdier top like […]

[…] you might end up with a riving knife that is too thick for a table saw. This usually happens with router tables that are repurposed into table […]

[…] one MDF piece and put it beside the plywood on the sawhorses. Then push the plywood strip’s longer edge on channel one into the second […]

[…] The image below is my homemade table saw with a built-in router. […]

[…] based on the fact that a majority of the food we consume at mealtimes is served hot. If you have a plywood table and a morsel of cold food hits the table-top, eating it is not any more or less dangerous than […]

[…] Table showing pros and cons of Plunge routers […]