If you’re looking to construct your own speaker box, subwoofer box, or speaker enclosure, two of the choices you should consider are MDF and Plywood. During my time as 20 years as a joiner/cabinetmaker, I used to make lots of speaker boxes for clients. I found out that both vary in effectiveness, portability, and price. And here’s how they compare.

MDF that is 3/4″(19mm) thick will work well as a speaker box but I have found Plywood to be a little better. Laminating 2 pieces together to make them thicker is the optimal way for reverberation. MDF can be a little cheaper than plywood as well. I have found that both materials will work fine.

But the flip side is that you can make poor selection choices in both materials. This post draws from my 20 years of experience to cover everything you need to know before making a speaker box, including what features are desirable in its material and what you can do to make sure the speaker box is not just effective but also light on your wallet.

Let’s get started with a detailed comparison of MDF and Plywood.

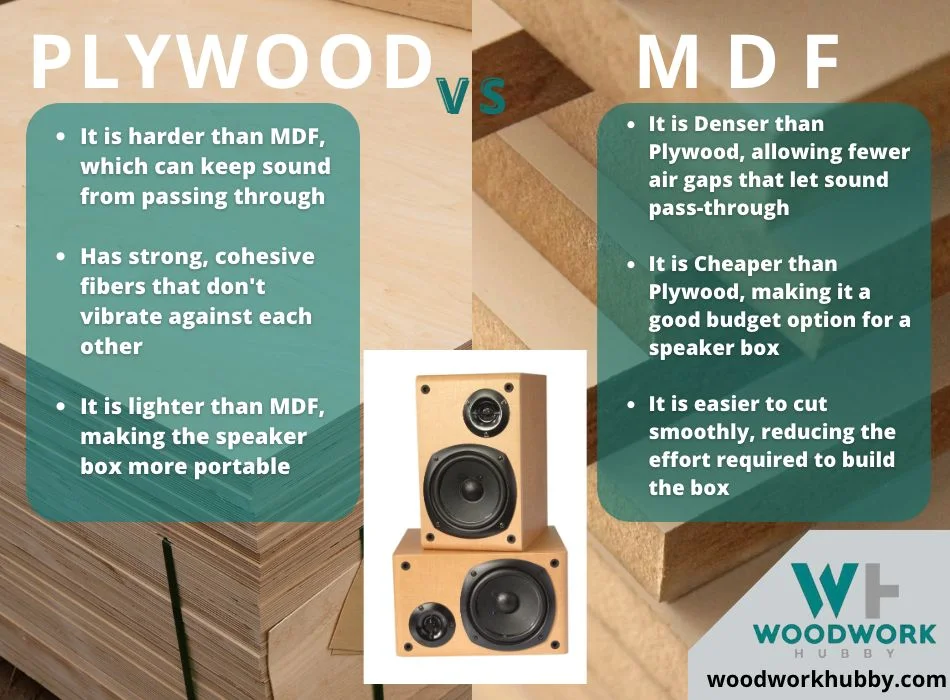

MDF vs. Plywood Speaker Box

To make the comparison between MDF and Plywood fair in this context, we must go over exactly what is required of a speaker box. Without making this a physics lesson, the gist of it is that a speaker box should be very good at canceling noise.

The better it cancels the sound that vibrates from anywhere else in the speaker cone, the better the sound from the front of the speaker reaches you.

When putting together your boxes, you need to how to prevent MDF from splitting. Check out my detailed articles below, which show you how you can screw MDF safely and tips for using both MDF and plywood.

So what does this mean for the material box? The speaker box material must:

- Feature as few internal air gaps as possible – Sound travels very easily through the air

- Be too hard to vibrate easily – The external surfaces of the box must not vibrate upon getting sound-bombed

- Have a strong core – The internal particles of the solid must not vibrate with sound waves.

So which of these two wood board materials fits this description better? Plywood is quite self-evidently the winner. Still, let’s have a side-by-side comparison and address a few nuances along the way.

| Speaker Box Requirement | Plywood | MDF |

|---|---|---|

| Air gaps | Present to varying degrees across different plywood grades | Not as prominent as in Plywood but are present and can expand (or contract) based on the environment |

| Must be rigid | Is always rigid | Not rigid |

| Have a strong core | Core strength depends on plywood grade | Doesn’t have a cohesive core. Internal movement of wood fibers is routine. |

From the above, you can see that while Plywood can be better for a speaker box, it is always better. You still need to select the type of Plywood that is better than MDF on all fronts. The problem with MDF is that it is practically impossible to find an MDF board that is better than Plywood of equivalent thickness.

| Pros/Cons | Plywood | MDF |

|---|---|---|

| Pro | It is harder than MDF, which can keep sound from passing through | It is Denser than Plywood, allowing fewer air gaps that let sound pass-through |

| Con | It is more expensive than MDF of equal thickness. It can be more expensive than solid wood for a speaker box. | It is Softer than Plywood but can be laminated for extra strength. |

| Pro | Has strong, cohesive fibers that don’t vibrate against each other | It is Cheaper than Plywood, making it a good budget option for a speaker box |

| Con | Costs more than MDF, which drives up the cost of the project | Has short fibers that can resonate easily |

| Pro | It is lighter than MDF, making the speaker box more portable | It is easier to cut smoothly, reducing the effort required to build the box |

| Con | It is harder to cut smoothly, which makes it difficult to work with | It is heavier than Plywood, making it harder to move around |

Is Plywood Better Than MDF for Speakers?

Plywood is better than MDF of equal thickness as it is more rigid and allows less sound to escape from the side of the speaker. Where Plywood is made of solid plys of fibers that go from end to end, MDF is made up of random wood fibers glued together in a flat mold under pressure. Sound travels more easily through MDF.

To make sound move less through a board like MDF, you need to have a thicker MDF board. It is possible for a thick MDF speaker box to outperform an extremely thick plywood speaker box. But in common instances, plywood speaker boxes win.

This applies to subwoofer boxes as well as echo boxes for mobile phone speakers because the underlying principle is the same. The box should cancel noise in every direction except one. And while MDF can dampen it, it fails to cancel it to the extent that Plywood does. That said, if you have MDF boards lying around, you might want to know whether they would be any good for a speaker box.

Can You Use MDF for Speaker Box?

You can use MDF for the speaker box, but for it to be effective, it must be 3/4-inch (19mm) thick. The speaker box will be heavier than Plywood and might consequently not be as portable. But it will be better than not having a speaker box at all.

There are two main ways to improve MDF’s usability as a speaker box material. The first is to make the MDF sheet thicker. The thicker the MDF board, the more sound it will absorb. However, MDF is already pretty heavy, so this variable can be a drawback.

The second is to get the MDF sheet laminated, which can increase the rigidity of the overall board. When it becomes hard for sound to vibrate through the solid lamination, the internal fiber structure of the MDF doesn’t present as much of a functional problem.

If you are planning to make a speaker box out of MDF, you may want to read the article if you can use pocket holes on MDF.

Is Plywood Good for Speaker Boxes?

Plywood is good for speaker boxes only if it does not have air gaps, is made with high-grade adhesives, and is sufficiently thick. Plywood must be at least 1 inch (25mm) thick to be good at absorbing sound, and if it is 3/4 inches (19mm) thick, it might not be as good as Plywood at doing so.

Best practices for getting Plywood for a speaker box:

- Use A-grade plywood – Plywood sheets are graded based on quality, with A being the highest. A-grade plywood is best for speaker boxes because it speaks for wood-fiber integrity.

- Look for Voidless plywood / Baltic Birch Plywood – If the Plywood is not of high quality, the board might have broken fibers and holes on the inside. Even the tiniest holes are air traps that allow sound to travel through.

- Find Plywood with the strongest adhesives – The wood fibers are held together with glue in any wood board. Strong adhesives keep the individual fibers from resonating with sound and letting it travel.

The best Plywood to make speakers out of is Woodcrafter 1″ Thick Baltic Birch Plywood. It is made in the USA and is thicker than the diameter of a quarter. It is manufactured in the USA, and there are no obvious compromises in its quality.

However, it is quite expensive, and pre-built speaker boxes that are more effective are priced lower. Why is that? Because Plywood is not a very budget-efficient material to use for a speaker box. You can technically get a really good speaker box made from Plywood but at what cost?

What Is the Best Material To Make Speaker Boxes Out Of?

A video showing the best material to make speaker boxes.

The best material to make speaker boxes out of is wood. Thick Plywood with high-quality adhesive can be an alternative. But since thick Plywood is quite expensive, MDF that’s 3/4-inch to 1-inch (19-25mm) thick is a better budget option.

Here’s the rationale:

Solid hardwood is the firmest, gap-free version of wood. Plywood is made from ripped fibers placed perpendicularly and glued together. Plywood is preferred over wood in cabinetry and similar projects because it is cheaper. For a speaker box, you need really high-quality plywood that is thick and of high quality. And that can be more expensive than actual wood! So why buy that if you can just use wood?

The best product for a speaker box would be Forest 2 Home Hard Maple Bundle. It costs less than Plywood of equal thickness and has lower odds of internal defects and air gaps.

It is also possible that you just want something cheaper than wood. If price matters more than effectiveness, you might as well use MDF. The best product for a speaker box would be Forest 2 Home Hard Maple Bundle. It costs less than Plywood of equal thickness and has lower odds of internal defects and air gaps.

The product comes in a wide range of sizes including 1 x 3 x 24, 1 x 4 x 24, and 1 x 6 x 24, dimensions. It is possible to get boards that are close to your speaker box schematics. It also comes in varying board quantities, including a 4-board bundle, which would be perfect for a speaker box. This product has 120 reviews and ratings, with the collective average rating standing at 4.7 out of 5 stars, with 94% of customers giving it 5 or 4 stars. In contrast, a cheaper item for your speaker box raw material would be a 3/4-inch (0.019 meters) MDF square.

| Recommended Speaker boxes made of Plywood or MDF | Where To Buy? |

|---|---|

| Forest 2 Home Hard Maple Bundle – 1 X 3 X 24 inches – 7 Board Pack – Kiln Dried Hardwood – S2S – Includes Carpenter Pencil | AMAZON |

| Q Power QBOMB15V Dual 15-Inch (.38 meter) Vented Speaker Box from High-Grade MDF Wood | AMAZON |

| MDF Sturdy Constructed Speaker Boxes | AMAZON |

Final Thoughts – MDF or Plywood for Speaker Boxes?

MDF and Plywood can both work passably for a speaker box. If you really want to double down on quality, use solid wood or A-grade plywood and make the speaker box thick enough to absorb sounds coming from every direction other than the front of the speaker cone.

-

MDF or Plywood for Speaker Box? 20 Yrs Experience

If you’re looking to construct your own speaker box, subwoofer box, or speaker enclosure, two of the choices you should consider are MDF and Plywood. During my time as 20 years as a joiner/cabinetmaker, I used to make lots of speaker boxes for clients. I found out that both vary in effectiveness, portability, and price.…

4 responses to “MDF or Plywood for Speaker Box? 20 Yrs Experience”

[…] One such decorative project is the MDF box. It is a practical project you can make with the MDF leftover from your main project. The following video shows the steps you must take to make an MDF box. […]

[…] average MDF shelf is weaker than its plywood equivalent. This is in part due to MDF’s internal structure. Over time, MDF starts losing […]

[…] biggest drawback for a starting woodworker is that plywood costs more than MDF of equal thickness. That’s why I recommend using MDF for […]

[…] Here are the drawbacks of an MDF router table compared to plywood. […]