During my 25 years as a joiner/cabinetmaker, we often were asked to supply painted doors to a kitchen. MDF was the best choice of material so I often had to spray paint 30-40 panels per kitchen with different types of single-part and 2-part paints. Here is what I know about painting MDF and if it warps when painted.

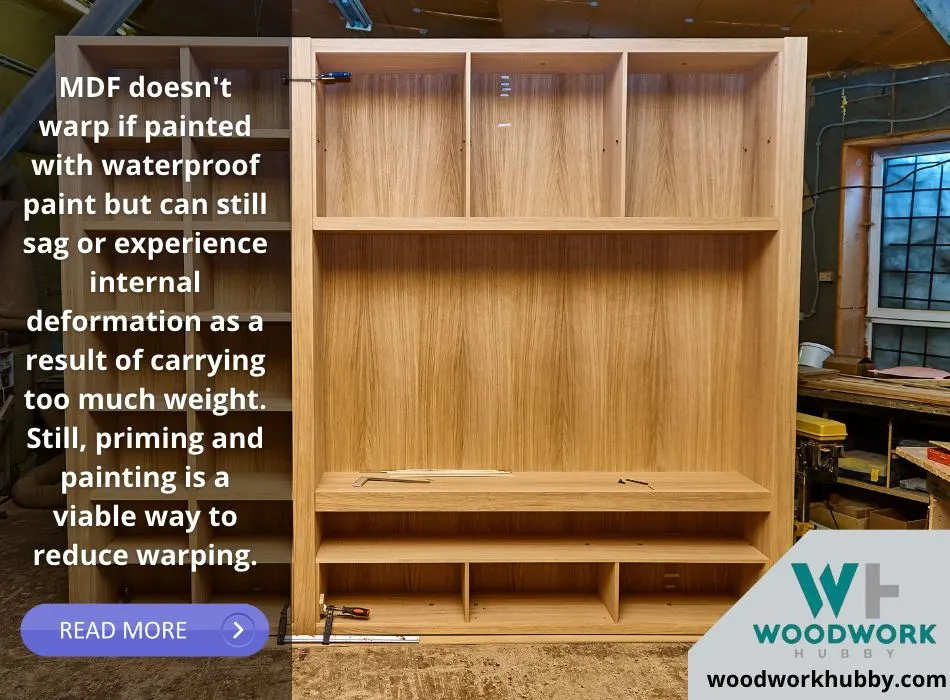

In general, MDF does not warp when painted provided the same number of coats of paint are applied to both sides and its edges if possible. In my experience, MDF will warp when only 1 side is painted. This is due to the MDF being able to draw in moisture on the unpainted side.

In this article, you will discover 10 things you can do to avoid or fix warping and deformation in MDF. Throughout the article, the different causes of warping will also be explained to minimize the chances of your MDF project going south because of an unplanned shape change.

How Do I Stop My MDF From Warping?

To stop MDF from warping, you simply need to keep it away from heat and moisture. Sealing the MDF can also work because it prevents moisture from getting to the core of the wood board. Finally, you must avoid putting too much weight on MDF.

Read my article here on how to screw MDF without splitting.

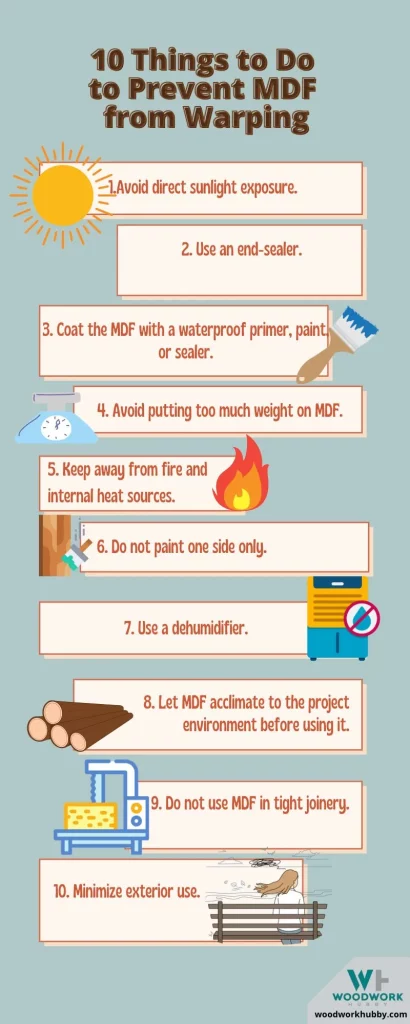

Here are the 10 things you can do to prevent MDF from warping.

| Tactics to reduce MDF warping | When to use | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Avoid direct sunlight exposure | If the MDF board is very thin | |||||||||||||||||||

| Use an end-sealer | If you cut the MDF board | |||||||||||||||||||

| Coat the MDF with a waterproof primer, paint, or sealer | It is advisable in all instances but mandatory in high-humidity applications. | |||||||||||||||||||

| Avoid putting too much weight on MDF | In all instances | |||||||||||||||||||

| Keep away from fire and internal heat sources | When using MDF for interior projects. | |||||||||||||||||||

Do not paint one side onlyIf the paint and primer coats are impermeable Use a dehumidifierIf the environment is too humidLet MDF acclimate to the project environment before using itWhen you use MDF for doors, cabinets, and permanent fixturesDo not use MDF in tight joineryIf the environment has drastic changes in humidity levelsMinimize exterior useIn most casesA table showing ten things you can do to prevent MDF from warping.

Does MDF Warp Easily?MDF doesn’t warp as easily as standard wood, plywood, and some wood composite materials. However, it does change shape with ease when it is under a constant load. This is called sagging and can be confused with warping. MDF stands for Medium Density Fiberboard. It consists of wood fibers pressed together to a (you guessed it) medium density with adhesives. It is brought together under pressure inside a mold that produces the boards that appear as if they are solid planks. In solid wood planks, shape-changing happens due to warping. But in MDF, there is the possibility of internal movement of individual fibers as well. When MDF warps, individual wood fibers in the board expand because of exposure to moisture and humidity. When MDF sags, the fibers themselves may stay the same size, but they start moving away from each other because of the weight that is acting on the MDF board. Warping is less likely, while sagging is almost always expected when MDF carries any type of weight. Warping is also easier to prevent with appropriate measures like sealing. In contrast, sagging can be prevented only by avoiding the use of MDF in load-bearing projects. Knowing the differences between these two changes will help you fix and avoid them over the course of MDF usage. Can Warped MDF Be Straightened?Warped MDF can be straightened if it is addressed early. If you notice a slight bend in an MDF board, you can place a weight over the bent side to encourage it to get flat. This fixes internal fiber movement, especially in a hot environment. If the MDF has warped too much, it might not return to its original shape. That’s why you have to spot warping early. The later you notice a change in shape, the more weight you need on the board. But since prolonged weight-bearing causes internal movement, bent MDF can eventually get as flat as the surface under it. To straighten MDF, you need a flat surface that is stronger than MDF. Well-finished hardwood or hardwood plywood can work for that. You will be surprised at the malleability of MDF. It can be advantageous in some situations but can have serious drawbacks in others. What are the disadvantages of using MDF?The disadvantages of using MDF instead of plywood or hardwood all revolve around the fact that MDF is just not as strong. MDF is made up of shorter fibers held together with an adhesive. And its strength is entirely contingent on the adhesive’s ability to hold fibers together. You might be wondering, “aren’t plywood boards also made up of fibers?” Yes, technically they are also made of wood fibers but there is a difference. Plywood is made with extremely thin sheets of wood glued together. Each wood fiber goes from one end of the plywood sheet to the other. This means plywood’s weight-bearing is as contingent on the fibers’ strength as it is on the adhesive resin used to hold it together. MDF’s disadvantages come from having shorter wood fibers. And here is how they manifest.

How Do You Stop MDF From Bowing?MDF bows for two reasons, and as long as you can offset them, you can stop MDF from bowing. The first reason MDF bows is that their wood fibers absorb moisture. You can offset this by appropriately sealing MDF. The second reason MDF bows is because its internal adhesives liquefy. To avoid this, you have to keep it away from direct sources of intense heat. All in all, you can stop MDF from bowing if you keep it away from extreme heat and appropriately seal it with a waterproof wood sealer. Make sure the coat is end-to-end so that moisture does not get through to the wood content of the MDF. This will all but guarantee that your MDF does not bow. However, the possibility of sagging under weight still remains. So the third thing that you can do to make sure your MDF stays plain and straight is to avoid putting more weight on it than it can bear. How Do You Straighten a Warped MDF Board?Video showing how to flatten MDF Straightening warped MDF board is a matter of reversing the exact problem. While there are three possible solutions, you cannot apply them all without sniffing out the issue. For instance, if the wood fibers have expanded, but you assume the issue to be the loosening of MDF adhesive, you might end up focusing on the temperature instead of drying out the MDF. To straighten the MDF board, you have to figure out if it is bloated because of moisture or losing shape because of adhesive degradation. Once you know the problem, you can bring the MDF into a better temperature environment and place a weight over the deformed side to straighten it. If the MDF in question is bloated in some areas instead of being bowed in one direction, the problem is most likely that wood fibers within the MDF have absorbed moisture. In contrast, if the MDF starts bowing from a specific direction, the issue is most likely in the weight placed on the MDF and its internal adhesive integrity. Steps to straighten bloated MDF:

As soon as the MDF runs out of moisture, it has no room to change shape. That’s why you have to have the load, the bottom surface, and the dehumidifier all within your reach before you start this process. If you don’t have a dehumidifier, use a fan and an open window to have a somewhat similar effect. This will work if the MDF is bloated in some areas. If the MDF is bowing in one direction, then the problem isn’t in the individual wood fibers but in the movement of individual fibers against each other. To straighten bowed MDF, follow these steps. Steps to straighten bowed MDF:

To wrap it up, here are the 5 things you can do to fix MDF when it is changing shape.

Does MDF Warp or Bend?Before you start working with MDF, you might want to know whether this engineered wood board warps more often, bloats more regularly, or bends frequently. Knowing the different circumstances in which this wood board can deform allows you to prepare and prevent such cases. MDF warps less often than it bends, but both of these can happen to an MDF sheet. Warping requires wood to expand or contract. Since MDF has very short fibers instead of long wood pieces, warping is unlikely. However, the glue that holds MDF together can weaken, allowing the overall board to bend. What Is the Difference Between Warping and Bending?Warping and bending might seem functionally the same: they deform straight sheets. But they are not the same thing in this specific instance. Warping refers to the wood content of the MDF straying from its original shape, while bending is either a consequence of fiber warping or the MDF adhesive coming loose. Warping can be prevented by sealing MDF as it minimizes the possibility of moisture getting to the wood fibers in the board. As long as the sealer is waterproof and covers MDF across all ends, it can be a viable defense against warping. There can be warping in plywood and other engineered wood boards, even if the boards are coated by a layer of waterproof sealer. That’s because the longer and thicker the wood fibers in the board, the higher the chances of the wood “breathing.” You don’t know what the moisture content of plywood is before you seal it. Any changes in that can lead to warping. Often plywood warps because of heat and the expansion of the solidified adhesive in the sheets. In contrast, MDF warps only with water exposure, and a sealer is sufficient to prevent that.

Final Thoughts – Does MDF Warp When Painted?MDF warps only if its wood fibers absorb moisture. It is already less likely to bloat like this compared to other wood boards. Still, whenever you cut MDF, you must use an end-sealer to reduce this possibility. While MDF doesn’t warp easily, it does sag and bow under its own weight or with exposure to extreme heat. It should be kept away from moisture, heat, and excessive weight.

About the author Latest Posts

|

2 responses to “Does MDF Warp When Painted? 10 Things You Must Do”

[…] can paint MDF outside with a waterproof primer if the board is average variety and without a primer, if it is an […]

[…] can be painted, too, but the MDF grain is easier to paint. Router tables don’t have to be painted, but if you prefer to make your workspace more […]