After being a cabinetmaker for 26 years, one common problem for us was joining 2 pieces of melamine where you couldn’t access one side to screw through. Pocket holes seemed like a good option at the time or were they? I thought I should share my experience from this time and tell you what I learned – can you use pocket holes in Melamine?

Pocket holes can be used in melamine provided you use more than 2 holes and glue to every join. Melamine board can be drilled easily for pocket holes although the joint is not going to be very strong due to the nature of the Melamine fibers.

In this article, you will learn more about melamine and screw joints including whether pocket holes can hold together melamine boards, the best practices of screwing a melamine board, and how you can drill a hole in one. By the end of this post, you will come out with actionable insights related to your project.

Can You Do Pocket Holes In Melamine?

You can do pocket holes in melamine but since the board is not made of melamine only, the screw can lose its hold. Most melamine boards sandwich an MDF or particleboard core. MDF features fine fibers bonded with glue, which isn’t the ideal structure to house an angular screw like a pocket hole joint.

You might think the harder melamine sheet will be able to maintain a hold on the pocket hole. But if you’ve read my post on can you use pocket holes in MDF, you already know that thin sheets of any type aren’t ideal for pocket hole joinery.

When a melamine board features a thin layer of melamine on the outside and a thick MDF or particle core at its core, then only the core of the board actually holds the screw head.

I found out recently that a lot of woodworkers hate pocket holes! I was unsure why so I did some research and found out exactly why do woodworkers hate pocket holes?

One may get away with pocket hole joinery in melamine decor but since the material is used most often for practical items like cabinets and floating shelves, pocket hole joints fall short of what’s required. A full-width dado would be ideal for melamine cabinets and a biscuit would work for lighter-weight projects.

Ultimately, every advisable joint in melamine carpentry is at right angles, which is far from a pocket hole screw’s acute 15-degree penetration. I always recommend using a good strong glue like Titebond 3 to hold these joints together.

Still, pocket hole joints are easier and are tolerated even in the instances where they shouldn’t be used. Melamine pocket holes seem to hold up for a while because of tough the exterior of such sheets is.

When it comes to holding screws in their place, the toughness of melamine boards can be somewhat of an advantage though it makes drilling inconvenient especially if it is your first time working with Melamine.

Do Pocket Holes In Melamine Work?

Pocket holes in melamine that is 5/8″ (16mm) thick will work well provided more than 2 pocket holes are used. Glue is also recommended to strengthen the joint and prevent movement.

I have found that excessive movement or racking on a joint in melamine with pocket holes, just works loose easily over time. This is because the core material of melamine is not strong enough to hold a screw head.

The below image shows some successful pocket holes in the melamine I drilled. The joint was quite strong using 4 holes.

How Do You Drill Holes In Melamine?

As mentioned earlier melamine can be pretty tough to drill through. And since the core of melamine boards is made up of wood fibers, they’re essentially particleboards with a tougher, laminate, exterior. While that might be an oversimplification, it stands true in the context of drilling.

Drilling through melamine is similar to drilling through laminate sheets, though the strength required varies. Drilling pilot holes is also super critical when screwing MDF together.

To drill holes in melamine, you need to use a standard twist drill bit which is sharp. Spade bits also work but it is important you know that the hard melamine surface makes drill bits blunt after many holes.

You can use a regular battery-operated drill or some people prefer to use a drill press but either one will work. Be sure to check out my article, can you use pocket holes for framing?

Best Practices For Drilling Holes In Melamine

Use carbide-tipped bits

When drilling holes in a melamine surface you shouldn’t worry as much about the melamine as you should about your drill bits. The tough surface of melamine can prove quite challenging for standard drill bits and can wear them out quickly.

If you don’t mind sharpening the drill bits then this isn’t an issue. But if you’re preparing multiple melamine items in an assembly-line style production, you’ll spend a lot of money on replacing the bits. It is better to spend more and get carbide-tipped bits so you don’t have to replace them.

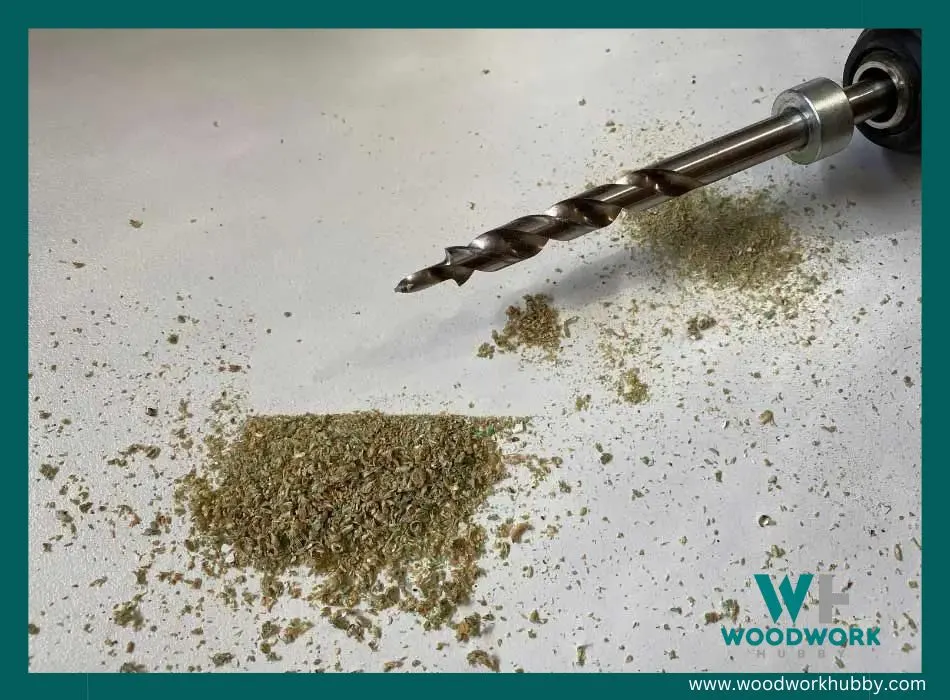

You can see from the image below, my regular drill bit that comes with the pocket hole jig, drilled through melamine quite easily.

Do not drill unless necessary

As mentioned earlier sandwich and dado are ideal for connecting melamine boards. Drilling is unnecessary if you can side-step screw joints. The only instances where drilling holes is acceptable in melamine board projects is if you know that trying any other type of joints will mess up the project.

Being a DIY craftsman entails being self-aware. If you are a master at screw joints or even pocket hole joints but know little about flatter sawed joints, you should prioritize what you have experience in. But that isn’t a license to be trigger-happy with your drill.

Prioritize steadiness

Drilling holes with bits like Makita D-13851 Hinge Boring Bit gives the best results since the surface area allows for evenness. To maximize steadiness, you should avoid using a hand drill.

Even if the boring bit has an even surface area and can make a hole that is of the same width at every millimeter, using a handheld drill might undermine the evenness of the hole.

A drill press not only helps you make a steady puncture through the melamine board but also ensures that the drill penetrates at the right angle, which maximizes leverage.

Sure To Check Out My Other Handy Articles On Pocket Holes

Can you use pocket holes for framing?

When Should You Not Use Pocket Holes?

As mentioned earlier, pocket holes are easy with a pocket hole jig. But you cannot assume they are useful just because you can lodge them more easily. Sometimes, the short-term ease isn’t worth the long-term trouble. In this section, we look at the specific contexts in which you’re better off avoiding pocket hole joinery.

1. Where right-angle joints are required

Whenever the joinery requires right-angle screws for stability, pocket hole joints will fall short because of their slanted anchoring. Usually, the pieces held together by a right-angle joint have significant pressure on the vertical or horizontal plane. In cases where the pressure is along the grain of the slanted joint, the boards can separate.

2. Boards that have MDF or Particleboard cores

When you lodge a pocket hole screw into an MDF or particleboard, you do not drill a hole in solid wood, you simply bore a path between fibers held by adhesives and epoxy. This leads to temporary traction but as time passes, more fibers around the screw start separating leading to the pocket hole becoming bigger than the joint screw.

3. When the project has to carry weight

If you’re building a closet, the bottom panels can have pocket hole joints because they don’t have to lift up the weight of the clothes and the stored items. But the higher panels and shelves carry so much weight that anything other than a right angle joint is going to lose traction over time.

Ask yourself whether the project has to carry more than 70 lbs of weight. If it does, and a significant amount of that weight falls on the joints then they should not be slanted. screws of any sort must be avoided as single points of attachment because the surface of a screw joint is too small.

Even when the joint doesn’t budge, the screw can eat into the wood, particleboard, or MDF.

4. When the joints are visible

For purely aesthetic reasons, a project where the joints are visible should not rely on pocket hole joints. Slanted screws are not visually appealing and do not inspire confidence.

This is one reason that woodworkers hate pocket holes!

If you use such joinery for commercial projects you may alienate customers as they might be unsure of how properly the item is put together. The connotations of being poorly put together have some basis in reality. A pocket hole joint isn’t as strong and lacks the longevity desired from cabinet joinery.

5. When the pocket hole jig isn’t compatible

Sometimes you will notice that a project isn’t compatible with a pocket hole jig. There can be several reasons for this. For example, the kind of screws you can lodge through the jig might not be suitable for the working material. It is also possible that the depth or width of the required screws cannot be delivered via a pocket hole jig.

If you have experience manually anchoring pocket hole screw joints, you will not have an issue at this stage but since most semi-professional woodworkers use a jig for their pocket hole joints, they would have a tough time working with materials like melamine or even particle boards.

Can I Screw Into Melamine?

Now that you know how unfit pocket hole screw joints are for any project that features particle boards, you might wonder if getting rid of the slant can fix the problem. While screwing into melamine at a right angle after drilling an appropriate hole is better than using a pocket hole joint, you have to pick the right screws.

You can screw into melamine but if you want a joint to last long, you must opt for a coarse-threaded screw and always use a pilot hole. Standard screws meant for metal and wood do not provide lasting traction in the particleboard interior of melamine.

See my full article on what size pilot hole is best. I also wrote about what is a clearance hole which is also helpful when screwing into melamine.

Things To Avoid When Screwing Into Melamine

Previously, we looked at the best practices of drilling into melamine. But even if you do not follow the recommended advice, you will not be in trouble. However, there are certain things you must avoid if you want to have a decent project crafted from melamine boards. In this section, we look at the mistakes you must avoid when screwing or drilling into melamine.

Do not treat melamine like wood

According to Mordor Intelligence, Melamine demand is the highest in furniture and furniture-related markets, where it is often used as a replacement for wood. While a melamine board can fit in a wood crafting project, you should keep in mind that it is not made up of wood.

Its interior features shredded fibers/particles held together by an adhesive. Screwing into melamine as if it is wood will lead to poor joint strength.

Do not expect a clean cut

One of the most common mistakes made by those inexperienced with melamine is assuming it will not chip. No matter how you attempt to cut or drill melamine, chips will fly everywhere. While you can minimize the mess, you cannot avoid it.

Use masking tape over hole positions or use a sharp drill bit.

If you’re working from an apartment workshop, make sure to keep the carpet away from your workstation and your eyes properly protected. If you’re working in a garage, make sure you have a system in place to clear out the chips and sawdust.

Do not confuse woodworking melamine with dinnerware melamine

When you seek resources on working with melamine and the kind of joinery, adhesives, and stacking that works with said boards, you have to be careful. Dinnerware melamine is homogenous and is solid across its surface.

The tips and advice that apply to such melamine are far from the ones that apply to melamine boards. Woodworking melamine is different mainly because it isn’t homogenous and usually makes up only the top and bottom surface of the actual “melamine” board.

The rest is a particleboard core and can sometimes be an MDF. Very rarely will you find a homogenous melamine board in woodworking.

Which Screw to Use for Pocket Holes in Melamine?

As mentioned earlier, one of the greatest disadvantages of melamine is its relative coarseness, which makes it possible for screws to backslide. While it is harder for screws to shift angles within a melamine board because of the board’s homogeneity, it can go back if it faces resistance. To avoid this, you must opt for a screw with more structure.

You should use Confirmat screws for pocket hole joints in melamine. These screws are designed for structural assembly and can hold their position when lodged at an angle mainly because of their coarse structure.

Snappy Tools Confirmat Screw Two-Piece Drill Bit 7x 50mm

In the absence of Confirmat screws, any screw that is not big enough to poke through the board and is coarse enough to work on drywall can work on a melamine board pocket hole.

This assumes that the melamine structure doesn’t have extra pressure on it. In the presence of pressure, the board itself can end up giving way even when the screw retains its position.

How to Strengthen Pocket Holes in Melamine?

Chipboards have high coarseness, which allows the material to hold onto the right screws regardless of the angle at which they’re launched. Still, pocket holes have inherent weaknesses that need to be offset with certain woodworking choices.

Here are a few things you can do to make lasting pocket hole joints in a melamine board.

- Use 3/4 panels – When a melamine board is thick enough, you have more room for error when lodging a pocket hole joint. Longer screws can be used with 3/4 panels, and the screw length is one of the factors that dictate the longevity of the joint.

- Use coarse screws – Coarse screws ensure that there is little to no backsliding or angle shifting within the melamine board.

- Reinforce with an adhesive – Finally, the best thing you can do to make a pocket hole stronger is to use it alongside an adhesive that holds the screw in place. In my experience, liquid nails work very well for this purpose.

Final Thoughts – Can You Use Pocket Holes In Melamine?

Pocket holes in melamine can be successful but you must use extra holes, use glue and take care of how you use them. Not only are they difficult to screw into melamine, but they also fail to last a decent period.

Other joinery techniques are better suited for such boards. Keep the pocket hole jig for lighter weight projects featuring working materials with a solid core.