Have you ever wondered why woodworkers always drill a larger hole in the primary piece of wood before they put a screw in? This hole is known as a clearance hole and is very necessary for all woodworking projects here is why. What is a clearance hole?

A clearance hole is a hole that is slightly larger than the outside diameter of the threads on a screw but smaller than the head. This enables a tighter joint between two pieces of wood when screwed together and prevents jacking.

In fact in some materials, a clearance hole is mandatory to prevent the piece of material being screwed from cracking or splitting. Let me explain why and how this works.

What Is A Clearance Hole?

A clearance hole is a hole larger than the screw diameter and is drilled into the primary or top piece of wood.

What Is A Shank Clearance Hole?

A shank clearance hole refers to a hole that is drilled that is larger than the shank of a screw.

How Does A Clearance Hole Work?

When you are trying to screw two pieces of wood together, you first need to drill the top piece of wood with a hole larger than the diameter of the screw thread. This hole prevents the screw from grabbing on the first piece of wood as you screw the two pieces together.

If you do not have a clearance hole, the threads on the screw would bind against the grain on the top piece of wood and cause them to separate which is also known as jacking. When jacking occurs, the screw tightens itself in the top portion of the wood but does pull both pieces together.

Watch this video for a visual explanation.

What Size Clearance Hole is Best?

The size of the clearance hole usually depends on the material being worked with, but generally, it should be just slightly larger (about 1mm) than the outside diameter of the threads of the screw.

On softwoods, I usually use a hole that is about the same size as the threads of the screw. Hardwoods may require a slightly larger hole which would also help enable the screw head to bury flush with the top piece of wood being screwed.

I do see there are a lot of tables online that show what size hole you should drill, but I find these very overwhelming and confusing when you are in the middle of making something. My biggest tip would be just to drill a hole that is 1mm larger than the overall diameter of the screw threads.

If the screw falls through the hole and is stopped by the head of the screw, it’s perfect!

If you are a numbers person and would like to see what the perfect size clearance hole is, be sure to visit this page on pilot holes and I have a full chart there.

Just remember, only drill this hole through the top piece of wood. If you would like to see a chart listing the clearance hole sizes, this chart will be very useful for you.

Do you drill Clearance holes all the way through?

The clearance hole is usually drilled right the way through the top material only. If you did drill a clearance hole through both pieces, your screw would fall straight through! Not a great start for your project. Just remember, clearance holes go through 1 piece of wood only, not both.

When Should You Drill a Clearance Hole?

You should always drill a clearance hole when you are using a screw that is fully threaded. This prevents the top material from jacking against the bottom material.

A partially threaded screw sometimes does not require a clearance hole as long as the screw threads are engaging in the bottom material and not the top material. This is why some screws have threads only partway up the shank.

Clearance is also very necessary when bolting two pieces of wood together. In this case, you are using a bolt, not a screw. The same rule applies though, always drill a hole slightly larger than the bolt shank itself. Obviously, when you plan on bolting 2 pieces together, this clearance hole will pass right through both pieces.

Guide To Drilling a Clearance Hole

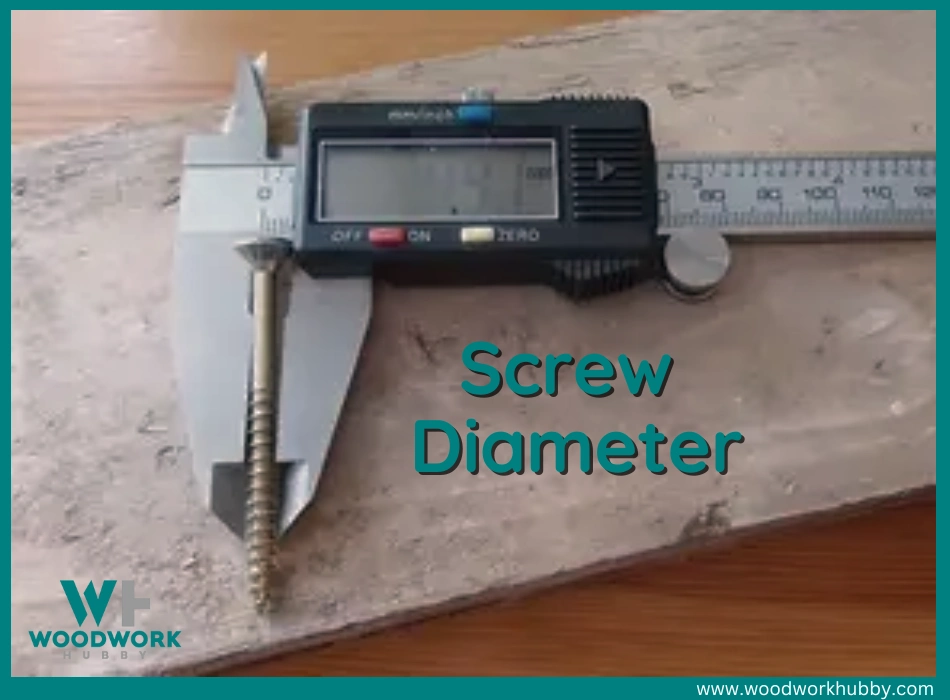

Step 1. Measure The Screw Diameter

You can use calipers or a ruler to roughly measure the diameter of the screw. As you gain experience, you can hold the drill bit against the screw rather than measuring.

Step 2. Choose The Drill Bit

Pick a drill bit that is 1-2mm bigger than the diameter of the screw.

Step 3. Drill Through The Top Workpiece Only

The top piece of wood needs to be drilled with a clearance hole. The bottom piece of wood gets a pilot hole.

Step 4. Tighten the Screw

Be sure the bottom piece of wood contains a pilot hole and then screw the blocks of wood together.

Can I Create a Clearance Hole Without a Drill Bit?

I have seen people try to create a clearance hole with the screw itself. They will drill the screw into the top piece only and then back it all the way out. The idea is that the screw creates a hole. This generally does not work as the screw only creates a hole as big as its shank and the threads themselves will still bind in the wood.

Further to this, driving a screw into the timber without some sort of hole creates small cracks which over time, can grow bigger and cause your screw to become loose or fall out. I recommend you take the time to grab a drill bit and drill the proper size hole.

Sometimes you don’t need one

If you are screwing together thinner pieces of wood that are only 5mm thick, you might get away without needing a clearance hole.

This is because the screw threads could easily slip through fewer grains of wood and pull you’re joint together. However, as I always say, if a job is worth doing, it’s worth doing right! Drill a clearance hole.

Other benefits of Clearance Holes

Clearance holes can also be your best friend. Have you ever tried screwing a joint together, and the 2 pieces don’t line up along the edge properly? It happens to me all the time.

If you have drilled a clearance hole, you could back off the screw and then tap the wood into alignment because the shank of the screw can move around inside that hole you drilled. Then just re-tighten the screw. The job is done!

Below is a list of the benefits of using clearance holes:

- Prevents jacking

- Get tighter joints

- Easy to align joints

- Prevents splitting

- Easier to countersink screw heads

- Keeps screws aligned

- Prevents screws from breaking

How Can I Speed Up The Process?

I understand – you want to do the job right but you don’t want to have 3 different drills for all of these attachments just to put one screw in. Luckily there is an easier way. Instead of drilling a clearance hole and then a pilot hole, you can do this all in one step. I always use these drills and they save a lot of time and you only need 1 drill bit.

Conclusion – Screw Clearance Hole

A screw clearance hole is a hole that is larger than the diameter of a screw and is used in the top material to ensure both pieces of wood are fixed together tight. I hope you now understand the importance of a clearance hole and why we use it in woodwork.

FAQ

What Is A Tapped Hole?

A tapped hole is one with threads inside of it and can be in wood, metal, or plastic. Once the hole has been tapped, you can then insert a threaded bolt or similar which will simply screw into those threads.