Trailer floors need to be laid to make a trailer more liveable. Standard flooring options include single-layer flooring as well as subfloors with a top surface. In both instances, OSB and plywood remain the top contenders. It is, therefore, understandable why people wonder which one of these two is better for a trailer floor.

Plywood is better for a trailer floor in terms of sturdiness, while OSB is better for the budget. Plywood resists moisture better, but OSB can be sealed to a similar effect. Since OSB is a cheaper choice, most DIYers prefer it over plywood.

In this article, we will go over the different strengths and weaknesses of plywood and OSB in this specific context. You will be surprised at how well OSB fits this use scenario despite being weaker than plywood of its equivalent thickness in almost every other situation. So, let’s get started with OSB’s compatibility with trailer floors.

Can You Use OSB for a Trailer Floor?

OSB is heavy and is often seen as “weaker” than other plywood because it doesn’t have grain-like plywood, which is made from broad layers of wood peeled and glued together in opposite directions. The reputation that OSB has is true to an extent. From shelves to cabinets and ceilings to drawer bottoms, plywood is generally the stronger choice. But when it comes to floors, OSB doesn’t seem as weak.

You can use OSB for a trailer floor because it is strengthened by compression applications. When a force acts on OSB from both ends, it is at its sturdiest because of its high sheer strength. More importantly, it is cheaper and comes in longer boards.

So there it is: OSB works on trailer floors. But is it the best choice? Are there consequences and handicaps to this selection? These can be clarified further with a deeper look into OSB. Let’s examine the pros and cons of OSB for trailer floors. This will help you decide if OSB is right for your trailer floor.

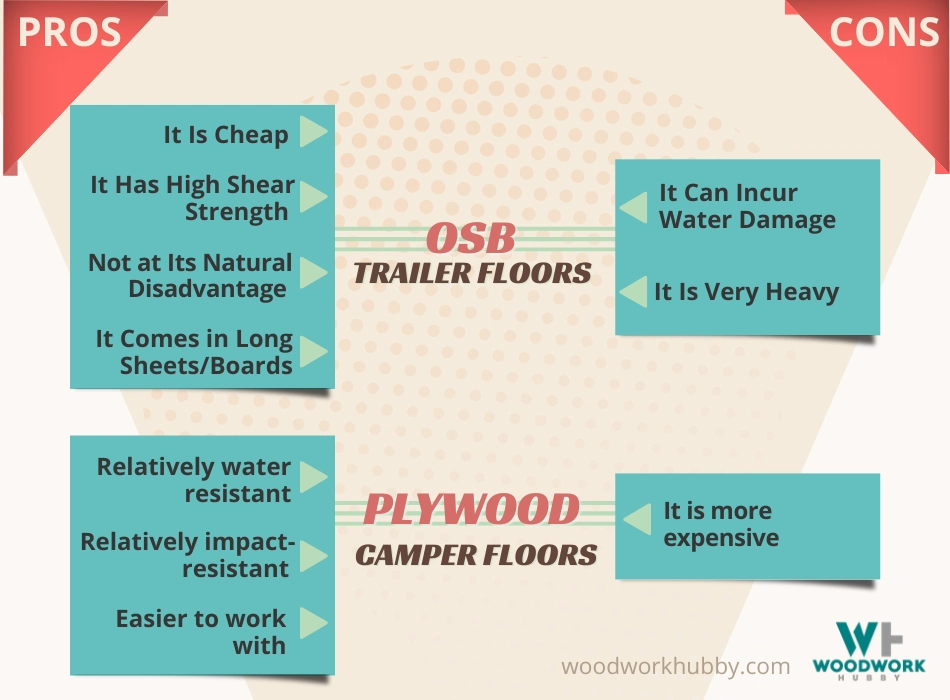

The Pros of OSB Trailer Floors:

It Is Cheap

One of the most common reasons for OSB being adopted for trailer floors is that it is quite cheap. It would cost 4 times more to get plywood as thick as OSB.

It Has High Shear Strength

OSB beats plywood in shear strength. While the flatly placed sheets of plywood can move against each other, the odds of individual strands in the OSB moving in a similar fashion are much lower.

It Is Not at Its Natural Disadvantage

OSB is at a natural disadvantage when it carries weight with nothing underneath it. The OSB can start bowing under heavy weight. But when there is support underneath, OSB is at its strongest. That’s why it makes for a liability-free cheap alternative in flooring.

It Comes in Long Sheets/Boards

Finally, there is a construction advantage to using OSB instead of plywood or other types of engineered wood. You don’t have to saw and glue multiple boards in multiple directions to cover your entire trailer floor. Long OSB boards generally cover a large portion of the average trailer.

The Cons of OSB for Trailer Floor:

It Can Incur Water Damage

In my estimation, this is the only drawback of OSB. Because wood strands in it are chunkier, they can swell with moisture presence just like normal wood. And they swell more than plywood. Water can get spilled on the floor repeatedly.

There is also the possibility of high moisture from cooking, showering, etc., in the trailer. All of that depends on trailer activity and amenities. This drawback is most evident on the sawed-off ends.

It Is Very Heavy

This drawback has more to do with the process than the actual end result. OSB floor-laying is back-breaking work. And it was just as back-breaking when I started woodworking as it is now, 20 years later.

Offsetting OSB Drawbacks:

Given that two of the greatest OSB drawbacks, in this case, are its tendency to swell with water exposure and its relative heaviness, there are two simple fixes that can make OSB more acceptable as trailer floor material.

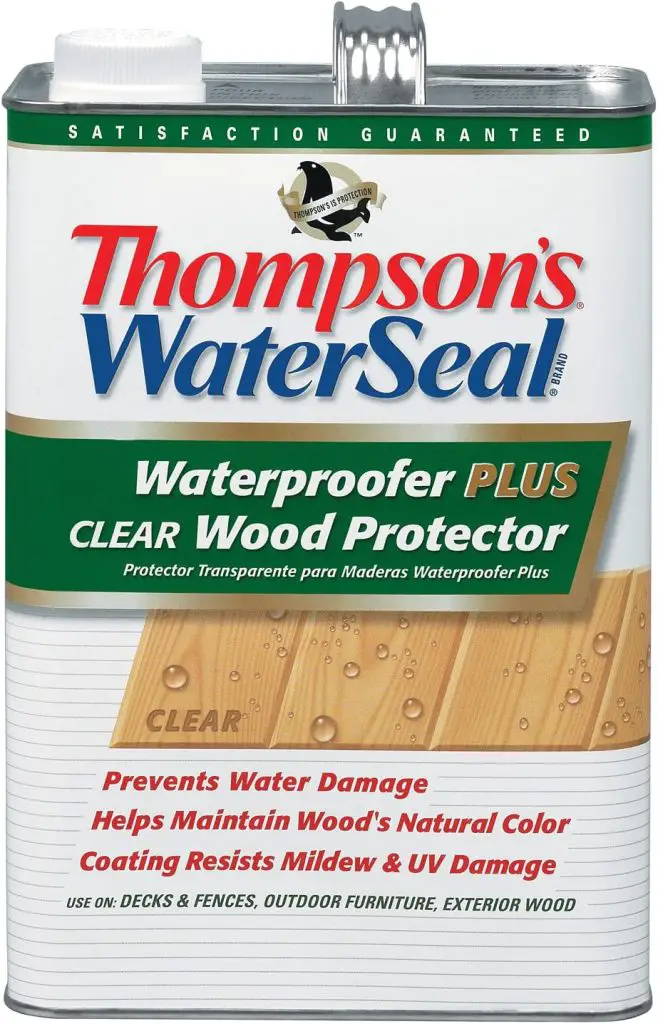

The first solution is to use a waterproof sealer/primer to fix OSB’s vulnerability to water. This is a no-brainer in this specific use context. OSB used as wall sheathing doesn’t have nearly the same exposure to water as a floor. So treat this as a mandatory expense on an OSB floor. Moreover, if the OSB needs to be cut for the floor project, it definitely needs an end-sealer coat, or it will swell at the edges.

Thompsons Waterseal is my go-to for OSB sealing because I find it cost-effective and also just effective. It can be used in other woodworking projects as well, which is always a plus for me, and it helps protect the wood from not just water damage but just traffic and usage damage. With an average rating of 4.7 out of 5 stars, over a hundred customers seem to echo my sentiment as well.

Its ease of use and sheerness is rated 4.5 out of 5 stars, while its value-for-money proposition stands at 4. People choosing OSB floors are smart with their budget, and this one is a budget-smart choice. But if you already have any wood sealer that you use to protect the wood from water, you can, by all means, use that.

Let’s move to the second fix. The fact that OSB is heavy cannot be offset with anything except outside help. I recommend having at least one more person helping you while you lay an OSB floor for your trailer.

Living With OSB Drawbacks

If you’ve waterproofed your OSB and have had a helping hand in laying it, everything is as it should be. But there will be some drawbacks that you will have to live with. I’ve listed them below so you know what to expect. And if you don’t want floor material with these drawbacks, you should probably look for an alternative material.

The Floor Will Get Damaged if You Drop Something Heavy on It

“Heavy” is a relative term. You could drop almost anything on an OSB board and see a dent. While an OSB floor can carry weight, it is not as resilient against impact. From jumping off the top bunk to dropping a kettle, many things can happen in a trailer or camper that cause damage to an OSB floor. You cannot fix this possibility, but you can fix the damage with wood-filling putty.

Strands Will Poke Out Upon Dragging

Heavy objects cannot be dragged on the OSB floor. They will catch the individual strands and pull them off the board. This breaks the overall seal and, of course, damages the OSB floor itself. The only way to live with an OSB floor is to avoid heavy dragging action on it. But in a standard trailer, the floor is painted over, and the trailer is shipped.

If you cannot have a trailer where dropping things and dragging heavy objects can damage the floor, look for sturdy plywood as a flooring option. In RVs and campers, there is a layer over the OSB or plywood that prevents any dragging action.

Video showing how to apply Epoxy Flake Floor Kit.

What Plywood Is Used for Camper Floors?

APA-trademarked plywood is used for camper floors. It is generally recommended for end-users and is also known as “structural plywood.”

It works as a subflooring and single flooring material. Sturdier than OSB and also more expensive, it is the prime choice for high-end and medium-end campers.

The fact that most camper producers use APA plywood for their campers suggests that it is quite evidently the superior choice. But still, delving into its pros and cons, though briefly, can be helpful when you want to make a material choice for your camper.

Pros of Plywood Camper Flooring

- Relatively water resistant – Plywood flooring needs to be coated in waterproofing material if it forms a single-layer floor. When it is used as subflooring material, it doesn’t have to need such sealing treatment. Still, it can resist moisture much better than OSB.

- Relatively impact-resistant – Plywood can stay uniform and unharmed when things fall on it. This isn’t the case with OSB.

- Easier to work with – Finally, Plywood is generally lighter, which makes it much easier to work with.

Cons of Plywood Camper Flooring

- It is more expensive – Pretty much the only applicable drawback of plywood is that it is expensive. Whenever I use it in any project, I offset it by buying plywood in bulk.

How Thick Should Plywood Be for the Camper Floor?

Any plywood board 1/2-inch in depth or thicker works for a camper floor. If you use it as subflooring, then half an inch should work. If the plywood is used as single-layer flooring, it should be 3/4-inch thick at a minimum.

The thicker the plywood is, the more durable the overall floor. And as good as that sounds, the fact of the matter is that plywood can get exponentially expensive as it increases in thickness. I believe anything beyond 1/2-inch is excessive for subflooring, and 3/4-inch is more than sufficient for a single-layer floor.

You can also use 1/2-inch plywood as a single layer and then use garage-floor epoxy to thicken the overall floor. But that is more experimental than most people are comfortable with.

Here is a video that goes over this:

A video about how to install self-leveling Epoxy over plywood

If you plan to pour self-leveling floor epoxy over OSB or plywood in your trailer, you should use Colored Epoxies Clear Coat Floor Epoxy. I won’t dwell on it much, but it is a great choice that goes well over plywood, OSB, and wood in general. And yes, wood is also one option for trailer floors. Not a good option, but an option nonetheless.

Coloredepoxies 10002 Clear Epoxy Resin Coating 100% Solids,

High Gloss For Garage Floors, Basements, Concrete, and Plywood.

Zero odor

Impact-resistant high gloss elastomeric ultra-premium.

What Kind of Wood Do You Use for Camper Floors?

You use engineered wood for camper floors. It is not solid hardwood or softwood but a composite of wood fibers and adhesives that hold it together. Plywood and OSB are the leading options for subfloors.

Solid wood is more expensive, rigid, and vulnerable to water damage. That’s why you should try to avoid using it for subflooring. If you’re impressed by the wooden aesthetic of some trailer floors, you are very likely thinking about vinyl flooring. The vinyl floor has the illusion of grain but is not actually made of wood. It is 100% synthetic.

Still, it is a very good choice for trailer flooring because it can be installed with ease. It also comes off pretty easily. Provided that the subfloor is laid in already, you can use a vinyl roll and lay it on the top layer. Vinyl isn’t as vulnerable to water as wood.

Advantages of vinyl floors for trailer floors:

- Is seamless and fault-free – While OSB strands can be very obvious and, at times, unappealing, a layer of vinyl flooring over it gives the perfect wooden aesthetic without any flaws.

- Easy to install without assistance – Vinyl floor installation is as easy as unrolling a vinyl roll because that’s all you’re expected to do.

- Is 100% water resistant – Vinyl floor’s top layer is water-resistant? This makes it a decent flooring option for relatively vulnerable subfloors.

- Is cheap and relatively durable – Vinyl is cheaper than epoxy flooring, as well as hardwood floors. If you choose OSB for subfloors, you might as well stay budget-smart and get vinyl flooring over it.

- It is silent and comfortable – Trailers are small, and the last thing you want is for the floor to be a sound amplifier. Vinyl floors are warm and comfy, not just for bare feet but also for falling objects. There’s little clanking, and the subfloor doesn’t get damaged.

Final Thoughts – OSB Or Plywood For Trailer Floor

OSB and plywood both work for trailer floors but have their respective limits. OSB is heavy and can get scratched or bloated with ease. Plywood is sturdier but more expensive. For practical purposes, both work as long as the flooring layer over these materials is durable and water-resistant.

-

Secrets To Best Epoxy For River Tables And How To Pour Them

When I first started making epoxy tables I had no idea which epoxy to use. I spent countless hours researching the best epoxy for river tables and I came up with some epoxy that is so easy to use so I decided to detail everything here for you. The best epoxy for river tables is…

-

Can You Use A Nail Gun On Cedar Shingles? My Tips

Roofing has been one of the toughest things I have done as a woodworker. It was especially tough early on when I used to manually hammer nails into shingles. Eventually, I started using a nail gun and learned that different roofing materials are receptive to it to different extents. You can use a nail gun…

-

Best Blades To Cut OSB Board And Why I Use Them

I have been trying to make an OSB tabletop for over a year, but I keep delaying it. And one of the reasons was the splintering that happens when you downsize OSB. I made the mistake of not getting it at the project size and now have to cut it. Though I have blades that…

3 responses to “OSB Or Plywood For Trailer Floor – Ultimate Guide”

[…] comparing OSB and Plywood for flooring […]

[…] use both of these materials, but each one has its own advantages. In short, if you prefer using plywood instead of OSB for the roof, you can use it but must be ready to pay extra for thicker […]

[…] is the best wood for a workbench top, but since it is very expensive, most woodworkers use thick plywood. Plywood isn’t solid wood but features wood fibers bound by an adhesive stronger than OSB. This makes it the best material for a workbench […]