If you want to build a garage, you must budget for the materials you need. For garage walls, you could go the brick-and-mortar route, the shed route, or the hybrid route. In my experience, a drywalled garage with wood board sheathing, as well as a wood board garage, can both work if you know which wood board to use.

OSB is better for garage wall sheathing while plywood is better for garage wall exterior. OSB is generally thick, which can provide sufficient sound insulation and help regulate garage temperature. Plywood is tougher against impact and can keep the garage from getting damaged by the elements.

In this article, you will learn about the key strengths of each wood board and the extent to which their respective pros and cons are valid for garage walls. You will also learn the key structural differences between these boards and the best garage wall positioning for each one.

By the end, you will be able to confidently choose between these two wood boards for your garage wall. Let’s get started by considering what one must look for in garage wall material.

What To Look For in Garage Wall Material

For an accurate comparison between plywood and OSB for shop walls or garages, it is crucial to understand what one must look for in garage wall material. In this section, we will explore the metrics upon which you should judge garage walls.

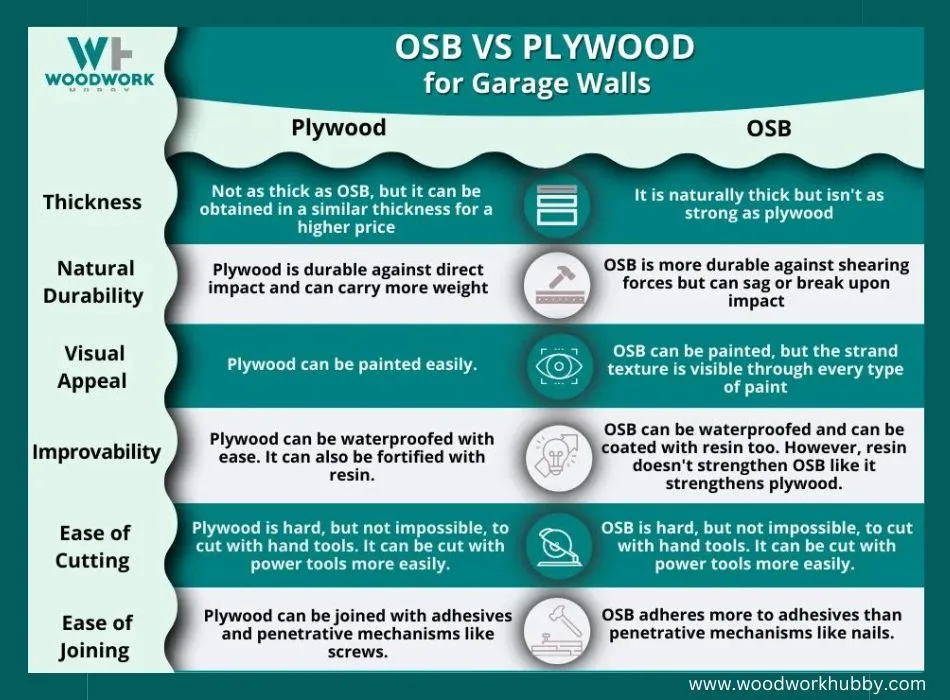

Thickness

Garage walls don’t need to be thick as the Empire State Building, but they need to be thicker than a trailer wall.

Natural Durability

The desirable wall material in this context has to be sufficiently thick and solid so that it has a sound-proofing effect to an extent. The noise of your power tools might not be silenced by your garage walls, but the sounds of the outside walls will ideally be kept out so you can work in peace.

Visual Appeal

The next important trait is the inherent durability of the sheets. If you stick enough sheets to each other with a strong enough adhesive, any material can become as durable as a hickory log. But natural durability minimizes cost and stacking burden. If a single sheet is strong enough, you don’t need to stack two together.

Walls protect you from the elements, prying eyes, distractions, and sounds. But if they are not good-looking, they can end up distracting you as well. There are rooms where one can afford to get distracted. A garage surely isn’t one of those. So it goes without saying that the material should look “good enough” if not “good.”

Improvability

Improvability refers to how well you can modify a product. Garage wall material should be easy to improve. Every material has its strengths and weaknesses, and sometimes you need to do a few things to improve the material you have selected. But for that, the material you choose should be conducive to improvement.

Ease of Cutting

Often, materials that can be improved (painted, waterproofed, etc.) are also materials that can be cut, sawed, or routed easily. But that’s not always the case. A garage’s wall material has to be easy to cut so it can be made to fit the parameters of your garage plans.

Ease of Joining

Unless you buy a precast cement wall or 3D-print your garage (both of which are possible in the world today), you need a material that can easily be joined with other panels of the same material or different materials. This is dictated by the joining method as well as the adherence of said material to the joinery used.

Is OSB good for shop walls?

OSB is good for shop walls because of its inherent thickness, sufficient durability, and low cost. OSB boards are thick enough to create a shed. You can double-up OSB panels or use other insulation methods for temperature regulation. OSB isn’t inherently waterproof but can resist water.

OSB needs to be covered in a layer of waterproof paint or primer for exterior use, though. Depending on how humid the conditions are in your region, you might need marine-grade paint or primer to make OSB (or even plywood) safe for external use.

The video is showing about how to install OSB as the interior garage wall

Having established that OSB is good for shop walls does not mean that plywood is bad. If it is, there is no point in comparison. Knowing why plywood is also good for shop walls is key to understanding the difference between the two. You will notice that the advantages both bring to the table are different from each other.

OSB, Plywood, and Impact Strength’s Relevance

Impact strength refers to a material’s ability to withstand impact. It corresponds with Janaka Hardness and correlates directly to material hardness.

The harder a material, the more impact it can withstand without breaking. Plywood has higher impact strength than OSB, and this is also why it can carry more weight.

But unless your garage walls are particularly heavy, the impact strength of the wood board isn’t really relevant. If you have a frame or pillars that hold up the roof and the wall material is mostly paneling the fills in the frame, it doesn’t matter whether the panels are made from OSB and Plywood.

If you think someone might take a sledgehammer to your garage walls, then the material hardness matters. Of course, it is always advisable to choose a material that is more durable. But when the extra durability isn’t a necessity, you must watch your budget first.

Is Plywood Good for Shop Walls?

Plywood is good for shop walls and garage walls located in a humid and low-wind environment. Their durability is unparalleled among wood boards, and they resist moisture better than OSB and MDF. Plywood has to be waterproofed if used in an exterior setting and can be expensive.

Plywood that is as thick as an OSB board is 3 to 5 times more expensive. The costs add up when you add up the sheets that are needed for a single garage wall. Plywood is stronger than OSB in every aspect except sheer strength. And that’s where the question of sheer strength’s relevance comes up.

Video showing how to line the garage wall with the plywood.

OSB, Plywood, and Sheer Strength’s Relevance

Shear strength is important in windy regions because wind can have a shearing effect (moving material against itself). A deck of cards is a good example of something with virtually zero shear strength. You can blow at a deck of cards, and the cards will move against other cards within the deck.

Plywood’s sheer strength is lower than OSB’s because plywood is constructed like a deck of cards. The fibers are stacked perpendicular to each other. However, adhesives used to glue them together keeps plywood from falling apart as easily as a deck of cards.

In contrast, OSB is put together like a traffic jam at a junction. When cars are stuck going in different directions, it is tough to make one lane move. OSB doesn’t have a smooth single-direction layer of wood fibers. It has hundreds of thousands of strands of wood oriented at multiple angles.

This is why it is called an “Oriented Strand Board.” The different orientations make the movement of the core strands against other strands quite difficult.

But a choice made on this factor alone would be one-dimensional. So let’s compare OSB to plywood across all dimensions for a clearer look.

OSB vs. Plywood for Garage Walls – Comparison

To sum it up: you can use both plywood and OSB for your garage walls as they function similarly to walls, except they can be put up with varying degrees of weight. Plywood is stronger, while OSB can resist shearing.

Getting plywood as thick as an OSB board is expensive, which is why I would not recommend it for novice to intermediate woodworkers. I have spent enough time working out of an OSB shed to tell you that you’ll be able to work in a garage with OSB walls.

Is OSB Good for Garage Walls?

OSB is good for garage wall interiors. It is sufficiently thick to have an insulating and sheltering effect. In some instances, you can use it for the shop’s exterior, but you need to waterproof it first. OSB and Plywood have almost interchangeable effectiveness in garage walls.

OSB, of course, is cheaper, which makes it an easy choice. However, its durability is comparatively lower than that of plywood, which can be problematic. In my experience, OSB doesn’t fall short in the durability required of an average garage wall. Not unless you have a cement roof, in which case even plywood might not be strong enough.

Both OSB and plywood can be purchased in (or amalgamated to) various thicknesses. So it isn’t like an OSB board has to be less durable than plywood. A thick enough OSB board can be sturdier than a thin sheet of plywood.

Is 7/16 OSB Ok For Garage Walls?

You should use 1/2 inch (12.5mm) thick OSB for garage walls. 7/16 inch (11mm) OSB can be added to the wall interior but is not suitable for standalone walls or exterior wall mounts. You should consider the fact that OSB’s thickness is one of its main perks. 7/16″ (11mm) plywood works better than OSB for exterior applications.

You can, of course, use 7/16″ OSB, but I am not comfortable recommending it. It seems too thin for a woodworker’s eye though a layman might find the difference between this board and the standard half-inch one quite minute.

What Kind of Wood Should I Use for Garage Walls?

You should use the wood board for sheathing your wall and exterior grade wood or other construction materials for the wall exterior. Wood boards that work the best for garage walls are plywood and OSB, both of which are durable enough for garage wall sheathing.

OSB and Plywood both need to be coated in waterproof primer or paint before exterior application. They also make excellent sheathing material for wall interiors. The trade-off between the cost and durability across both materials doesn’t make a functional impact on garage walls.

You pay more for plywood if you have a bigger budget. And you can use OSB and save money, though the resulting walls will be understandably less durable. Still, they will be functional. So whether you choose plywood or OSB doesn’t matter as long as you continue the garage-building process. If you pause and start overthinking these choices, you will unintentionally procrastinate and may end up losing momentum in the end.

| Wall Application | Description | Best Wood Board | Rationale |

|---|---|---|---|

| Wall cover | The exterior of a pre-built structure is covered with another material | Plywood | Plywood is naturally more weather resistant than OSB. It can also be coated more easily and comes in marine-grade varieties that don’t even need to be waterproofed. |

| Frame-filling | The frame is filled with panels of wood board, bricks, or drywall. The frame forms the skeleton, while the wood board makes the wall. | OSB | OSB is much cheaper than plywood and has higher shear strength. Since most of the heavy lifting is done by the frame, the shear strength and passable durability of OSB work wonders. |

| Interior Cover | If the wall inside needs to be covered up to be more aesthetic or to regulate temperature, a wood board, paint, or both could be used. | Plywood | Plywood is typically considered more aesthetically pleasing. It can be painted and doesn’t have a texture that pokes through the paint. But if you find the OSB looks to be an improvement for your garage or shop interior, you can pick OSB instead of plywood. |

| Sheathing | Wall sheathing is like interior covering, except it is more often for insulation purposes only. | OSB | OSB is cheaper and thicker. This thickness can insulate the shop from outside distractions while reducing the sound of the power tools used inside for the outside world. |

| Cohesive Wall | The wall structure is entirely built from one material aside from the pillars that hold up the roof. | Birch Plywood or Marine Grade PlywoodCohesive walls made out of wood board can work for small-scale sheds and shed-based shops. But for this specific application, you should use extremely durable plywood. OSB fails to work here, as does most plywood that isn’t built for construction purposes. |

Who Should Choose OSB Walls?

You should use OSB for garage or shop walls if:

- You need wall sheathing or interior paneling on pre-built walls – If you have a drywall construction or a shed with an empty frame, you can fortify it with OSB. OSB’s natural thickness works in your favor in this context.

- The roof of your garage is lightweight (your garage isn’t top-heavy) – Your garage’s roof can dictate the kind of wall material used in its construction. Alternatively, the garage walls can set a limit as to the kind of roofing that goes on it. Generally, OSB can hold the type of roof that a wooden garage or shop has. But if you choose to use a very solid roof type, you might end up needing a thicker OSB or sturdy plywood.

- You can find OSB panels that fit your schematics more easily than you can find plywood panels – In my estimation, this has to be one of the biggest factors whether you use OSB or plywood for interior or exterior applications. Since both materials perform to a functional extent in this case, the choice should be based on availability alongside convenience and affordability.

As a woodworker, I understand the importance of momentum. If you lose momentum trying to find plywood panels when you already have an OSB stack lying around, your garage may never be finished. If OSB allows you to act quickly, you should use it

Who Should Choose Plywood Walls?

You should choose plywood for garage or shop walls if:

- You don’t like maintenance work and fixing things once you’ve built them – Plywood walls, as well as plywood slapped onto wooden walls, is resilient. You don’t have to constantly repair the panels or replace them. Plywood lasts longer than OSB on the outside. In interior settings, it is not particularly durable than OSB. On average, if you make the more durable choice, you have to fix messes less often.

- You need wall exterior or paneling on pre-built walls – As mentioned earlier, plywood works incredibly well as a wall exterior, especially for walls that are made of less weather-resistant material. Plywood can be waterproofed to an exterior grade with a simple coat of waterproof primer. Its structural strength helps it stand up to impact, but its shear strength can be a limiting factor in areas with high-velocity winds.

- The roof of your garage is heavy and needs sturdier walls – Between OSB and plywood, the only time plywood comes out ahead as a necessity is when the roof of the garage is heavy. If you plan on using a wood board for a cohesive wall (as covered in the table earlier), you will need birch plywood or thick marine-grade plywood. OSB and even average plywood won’t be enough to make cohesive shop walls.

- Money isn’t a constraint, and you have a big budget – Plywood needs to be thick if you use it for walls. And the thicker the plywood, the more expensive it is. Sometimes, you have to slap multiple plywood boards to fill the frames in your schematics. In other words, one should not plan to use plywood unless one can afford it. Sometimes, intermediate woodworkers also make the mistake of buying a few panels without calculating the cost of all the panels that would be needed. Make these calculations before you get started.

- You can find plywood panels that fit your garage plans more easily than you can find OSB panels. – If money isn’t as big of a constraint and you can find plywood sheets within your budget before you find OSB panels, buy them. As a creator, I will always prioritize momentum. I have seen people lose momentum and leave their shops semi-constructed or in the planning stage (even worse) for years. I don’t want that to be you.

Should I Plywood My Garage Walls?

You should plywood your garage walls if your garage walls are made from material that isn’t modifiable. Plywood interior can make the surface paintable and will allow you to hang and shelf tools and materials you use while woodworking. It also creates a pleasant wooden aesthetic.

Reasons to plywood your garage walls:

- To hang tools – For this, you need to use plywood in your garage wall interiors

- To protect the garage walls – If your garage walls are made from material that is hard to repair, a faux exterior made from plywood can protect it. Plywood is easier to replace.

- To insulate your garage – You can use plywood to make your garage wall thicker, though OSB is better for this as it is cheaper and thicker on average.

- To replace the wall – If drywall in your garage is falling apart and you want to replace it with an alternative material, you can use plywood panels instead.

Final Thoughts – OSB Or Plywood For Shop Walls

OSB and plywood walls can be used in various ways to build or fortify garage walls. Both of them work for garage wall interiors with almost the same degree of effectiveness so feel free to pick either one. Whichever is within your financial reach and is easily available should be your choice for a wall interior. For wall exteriors, I would recommend marine-grade plywood.