When you get started in woodworking, buying the necessary tools can soon become expensive. For this reason, you may be tempted to go all-in just like I was. Keep reading as you may not need to. Do you really need a jointer if you have a table saw?

You do not need a jointer if you only do edge jointing. A table saw can be used to do this with a jig. If you need to do flattening and squaring on all four sides, you will need a jointer, thickness planer, and a good table saw to get the job done quickly, accurately, and with a smooth finish.

Power tools are intended to make the life of the woodworker easier and give the ability to perform workshop tasks quicker and more accurately. A jointer certainly does this when used for its intended tasks. There are other tools that you may already have in the shop that you could use to achieve the same goal, such as a table saw.

If you can use a table saw to replace a jointer, will it be efficient in the role?

What Does A Jointer Do?

If you are a woodworking newbie, you may not be familiar with all the terminology that goes with this craft. What is jointing? And no, it is not creating joints in pieces of wood, but it is a preparatory task that helps to create great joints!

Jointing is described as the process of putting flat, straight edges on wood boards prior to joining them together. A jointer is also important in creating square sides to a piece of timber. The jointer machine, as a power tool, replaces the function that the hand plane fulfilled before power tools became a thing.

A Jointer is essentially a power plane and is used to flatten and straighten the edges and faces of timber boards. But a jointer does have some limitations, and it is intended to be part of a process to flatten and square timber boards in conjunction with other tools to prepare the timber for the project.

How Does A Jointer Differ From A Table Saw?

A jointer is designed to take thin layers of the surface of the wood to leave a very smooth, flat, and straight edge. It cannot cut boards down from large pieces into smaller pieces. It is designed to be a tool that produces a finish to an edge of a board that is conducive to a very straight and almost seamless joint between two pieces of board.

This is the main function that a jointer is used for, although it is also useful to smooth down one face of the board to eliminate uneven surfaces and square the face to a jointed edge. Which brand should you use – Jet or Grizzly? I compared them both here.

A jointer differs from the table saw in that it only removes wood in small increments from the workpiece and cannot be used to cut large pieces of board into smaller pieces.

A jointer is used to square up one side and one face of a board. In preparation to finish the flattening and squaring of the board the other woodworking tools, such as a planer and a table saw.

Advantages Of Using A Jointer

A jointer has two reference surfaces, the bed of the jointer, which is perfectly flat, and the fence of the jointer, which is 90-degrees to the jointer bed. The combination of these two reference points will allow you to get one face of the board flat and one side of the board flat and perfectly perpendicular to the face of the board.

This process with hand tools or other power tools in the workshop would be slow and time-consuming, and less accurate than with the jointer.

Disadvantages Of Using A Jointer

There are a few disadvantages to using a jointer, some of which are related to the way the tool works and others relating to logistics in the workshop and your available budget.

- Cost. Jointers, even benchtop models, are not particularly cheap tools and add an additional expense that many woodworkers feel is not justified.

- Space. In many woodworking shops, especially home wood shops, space is at a premium, and the jointer is another tool that takes up valuable real estate in the shop. Did you know woodwork can be done outdoors? My article explains why you should

- Joint one edge only. You can only join one edge of the board on the jointer. The other edge must be jointed on another tool, using the jointed edge as the reference.

- Only square up one edge and one face. A jointer can only be used to square one edge and one face of the board. These jointed surfaces are then used as reference surfaces to flatten and square the other edge and face on other tools, such as a planer, and a table saw.

The biggest drawback of the jointer is that all edges and sides on a board cannot be flattened and squared by the jointer alone. The jointer is one step in the process of achieving this goal.

If you edge joint one edge of a board on a jointer, the opposite edge should be done on a table saw, using the jointed edge as the reference edge against the fence of the table saw.

It is not possible to join the opposite edges of a board on a jointer and keep these edges parallel to each other. Likewise, it is not possible to flatten both sides of a board on a jointer and ensure that they are parallel to each other.

What Does A Table Saw Do?

The function of a table saw, when you break its role down to basics, is to cut timber boards. This can be ripping boards, which is cutting the boards lengthways, or cross-cutting, which is cutting the board shorter, across the width of the board.

A table saw can be used to cut angles into the ends of boards for creating corners in joinery or fitting boards into angled spaces. This is not where the usefulness of a table saw stops. By changing the type of blade on the saw, the table saw can be used to cut dados into timber boards to create joints or slots in the timber.

You can also create a multitude of jigs that you can use with your table saw to create complex joinery cuts that would take a long time to produce if hand tools were used to make these cuts.

Various types of blades can be fitted to a table saw to achieve different types of cuts and quality of cuts, which makes the table saw a very versatile piece of equipment in the woodwork shop.

Can a miter saw cut a 4×4? You might be surprised by this!

Advantages Of A Table Saw

A table saw is seen as a must-have item in any woodworking shop, and of all the power tools in such a shop, this is the tool that probably most woodworkers would not want to do without!

There are several advantages that a table saw offers that have earned this power tool such as revered status.

- Speed. Table saws are fast and can cut and process timber at an incredible speed that saves literally hours of work in a workshop.

- Accuracy. Accurate and square cuts can be easily performed on a table saw due to the fences, miters, and jigs that are available for these tools.

- Versatility. The table saw can be used for many tasks in the workshop; it is not just for cutting timber down to size. It can be used to perform surprisingly delicate cuts in wood for many woodworking tasks. There are many accessories that can be used on table saws and jigs that you can build that further enhance the versatility of this tool.

- Easy to use. The table saw is not a complicated tool to use. It is easy to operate, and with the various fences and jigs available, it is easy to get accurate and clean cuts.

The table saw is probably considered to be the most indispensable power tool in the woodworking shop, and it is the power tool that most beginner woodworkers purchase first for their workshop.

Disadvantages Of A Table Saw

Even though the table saw is an extremely useful addition to a woodworking shop, they do have its limitations and some drawbacks.

- Size. Table saws are large tools because they are intended to be used to process larger pieces of lumber. As a result, they take up quite a bit of space in the workshop and require space to push lumber through the machine. There are portable versions of the table saw available, but they can only be used to process smaller pieces of timber since the work surface s smaller. You would need to support larger pieces with benches or sawhorses, which will then increase the space needed to that of a large table saw anyway.

- Dangerous. Of all the power tools in the workshop, the table saw is the one that inflicts the most injury on woodworkers, and the injuries can be life-altering! Often the cause of this is because the operator becomes blasé about using the tool and does not adhere to safety rules, but this is not always the case. Sometimes accidents just happen.

- Cutting injuries are only one type of danger from these machines; they can also kick back and throw pieces of lumber back at you at frightening speeds. It is, therefore, important to always follow safety protocols when using this tool and never take shortcuts or use it for a task for which it is not intended.

- Noise level. Table saws are noisy tools, but then again, most power tools have some level of noise associated with them.

The advantages of a power tool have kept the table saw as the top choice of power tool in the woodworking shop.

See my review of Jet & Grizzly Table Saws here!

Can You Use A Table Saw Instead Of A Jointer?

It is possible to use a table saw instead of a jointer, but only when it involves edge jointing a timber board.

Many people starting out with woodworking are working to a budget, and a jointer is one tool that does not seem to fit in the budget because of its limited functionality and the fact that it is one of possibly 3 tools that you would need to properly square up a board to be used in your project.

For this reason, people hesitate when it comes to purchasing a jointer to add to their already cramped workspace and put further strain on their budget.

It is not so easy nor safe to convert a table saw to function as a plane to join a face of a board, and the dangers of using a table saw to achieve this would outweigh the benefits.

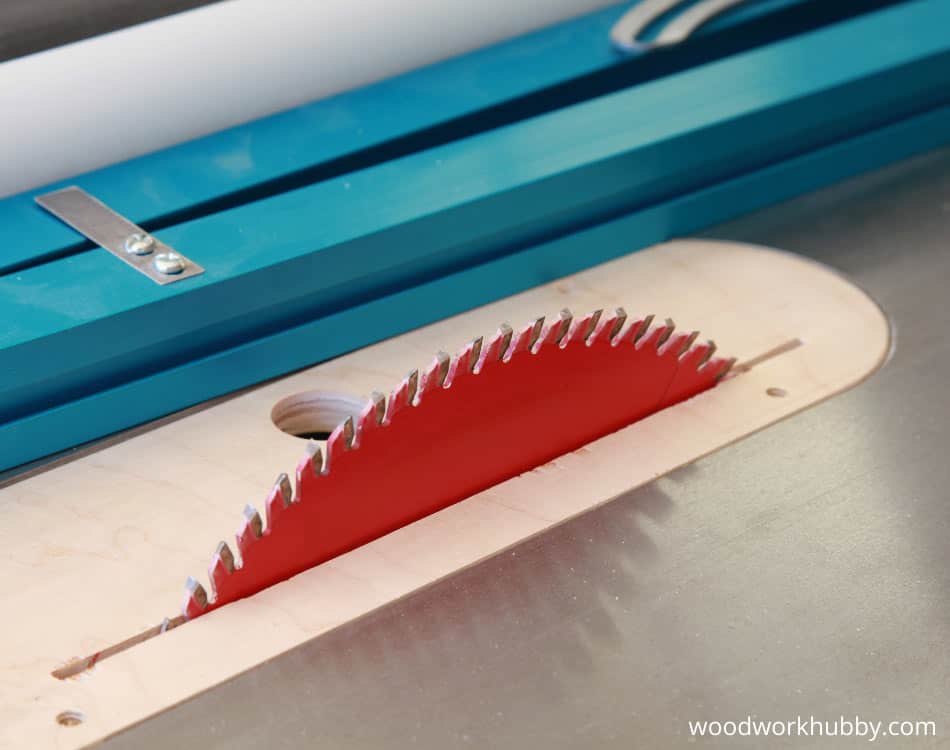

The only way that you can convert your table saw to operate as an edge jointer is to build a jig for your table saw that will allow it to function in this capacity.

The jig that you will create for this purpose will run against the existing fence of the table saw but will include two clamps that will secure the board to the jig while leaving an edge of the board hanging over the jig, which will be cut by the saw blade.

The jig references against the fence, which makes sure that the cut along the board will be parallel to the fence.

Once the first edge has been cut, the board is removed from the jig. The edge of the board that has been jointed is then pushed up against the fence of the table saw, and the board is run through the table saw again to join the second side.

Edge jointing in this way will make sure that both edges are parallel to each other and smooth and flat. This method provides an edge surface that is suitable for most woodworking projects that require parallel edges.

However, flattening the faces of the board is a challenge that is much more complex and is not easily done on a table saw. The board would need to be run through the saw on the thin edge of the board. The blade would have to be set very high to cover the width of the board, or the board would need to be covered with multiple passes.

While this flattening of a board can be done with some success on a table saw, it is a dangerous cut and should be attempted with extreme caution. If you need to flatten boards on a regular basis, it would be better to get a thickness planer to perform this task.

Do You Really Need A Jointer?

Whether a jointer is necessary or not will largely depend on the type of woodworking that you are doing, the demand for a quality final product, and your budget.

As we have mentioned, a jointer is one step in the process of fully jointing a board. In ideal circumstances, the tools that you need to perform this task correctly would include a jointer, thickness planer, and a table saw.

When these three power tools are used in conjunction with each other, you can very quickly process boards and achieve a very professional finish, which helps with the final visual appeal of the project.

However, if you mostly do edge jointing, you do not need a jointer since you can quite easily and safely do this on a table saw with your homemade jig.

For this reason, many smaller shops and home woodworkers would rather put their money into buying a table saw and a thickness planer rather than spending money on a jointer.

Conclusion – Do you need a jointer if you have a table saw?

So, do you need a jointer if you have a table saw? The answer depends on your situation and budget. If money isn’t an issue or space constraints aren’t too tight, then yes, getting both would be ideal since they work so well together.

However, if finances are tight or space is limited, then it might make more sense for you to just get a table saw since this is the most versatile option between these two workshop tools.

This is particularly the case since you can create a jig for your table saw to perform edge jointing to an acceptable standard. If you are a professional woodworker creating cabinetry and woodworking projects for sale, then you may come to the realization that a combination of a jointer, planer, and table saw provide enough of a time saver.

Investing in all three tools to get your projects out faster and maintain a professional finish!