Have you ever wondered why the end of your tape is loose? I was recently at my neighbor’s house and not liking his old tape measure, I decided to buy him a new one. A few weeks later we were talking about tape measures and he made a comment on the one I had bought him saying “I think it’s broken as the end is very loose”. I could not stop laughing! Why is the end of a tape measure loose?

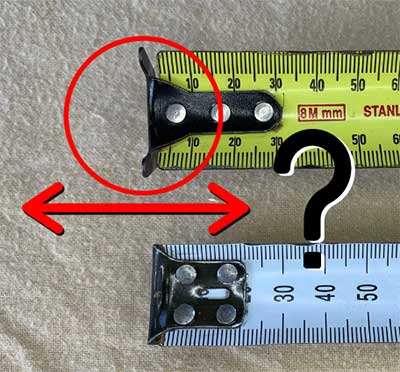

The metal end of a tape measure is loose to account for the thickness of the hook end. This movement allows accurate measuring whether you are measuring internally or externally.

The metal end of the tape measure varies but is usually around 1-2mm in thickness. This is why the end must move a little to account for that thickness. Let me explain what an internal or external measurement might look like.

Why Does The End Of A Tape Measure Move?

The end of a tape measure is designed to move in and out to account for the thickness of the metal on the hook end. This movement means you will get an accurate measurement whether measuring internally or externally.

Here are some of the best tape measures I like to use.

Don’t stress! Your tape is not broken. The end is meant to be loose.

Internal And External Measuring

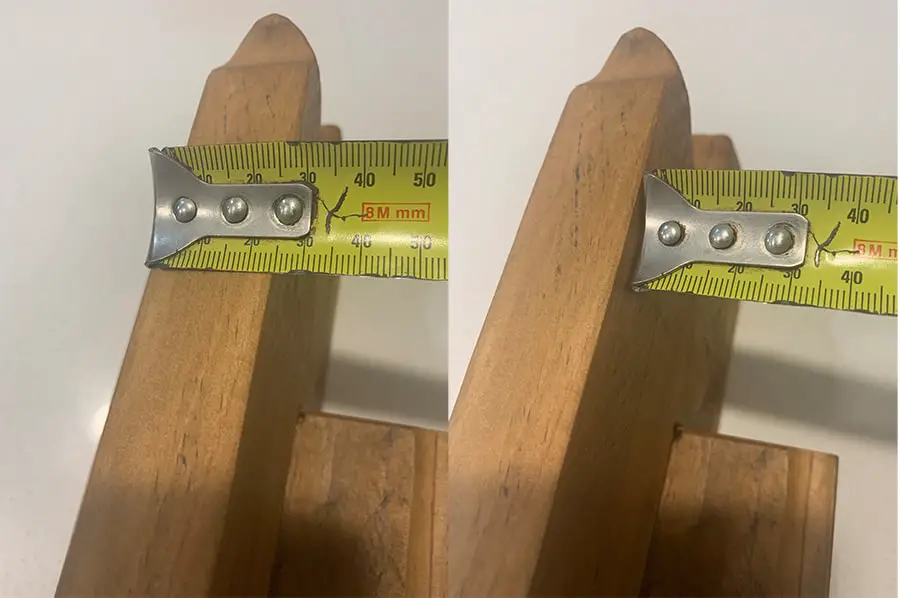

Let’s say you need to measure the length of a box. You would Hook the end of the tape over the side and then measure it (Externally). Now imagine that a wall or another part obstructed you from hooking the end of the tape.

The only way to measure now would be to butt the end against that wall or part. (Internal) If the end of your tape did not move, you would have 2 different measurements. The video below will explain this in detail.

How Loose Is Too Loose?

I often get asked how to know if the end of the tape has too much wiggle room back and forth. This is always a good thing to check especially on new tape measures. The way that you check is by just doing the actual process I show in this video below. If you take both of these measurements, then you should get the same dimensions both ways.

Loose Tape Measure – Here’s How To Adjust It

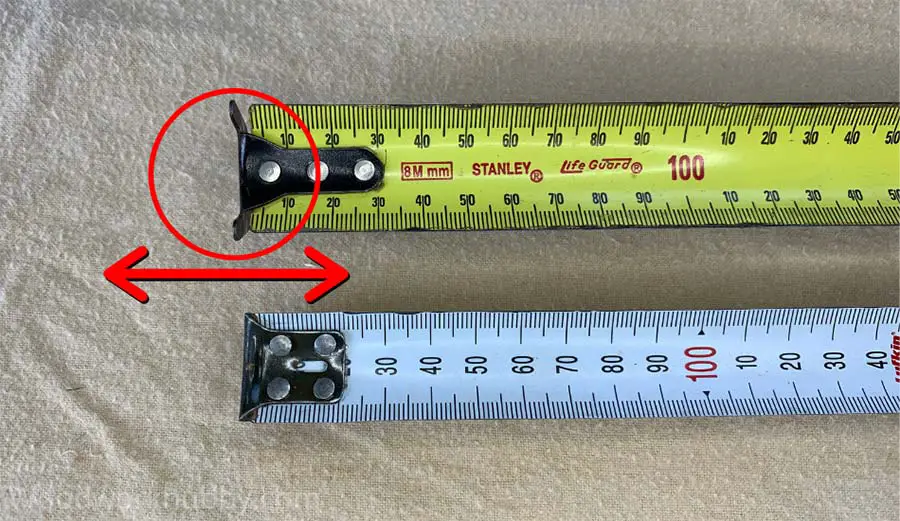

Okay, so if you have done the above process and your measurements are coming out differently, then you have either one of two problems. The Hook end may be either too tight or too loose.

The end is too tight – If the external measurement is larger than the internal one. Try to loosen the rivets holding the end on. This can be tricky and if you cannot move it, you may need to consider buying a better tape measure.

The end is too loose – If the external measurement is smaller than the internal one. Place the rivets on the end over a steel corner. Hit the rivets with a hammer to clamp them down tighter and then recheck your measurement.

How To Protect The Metal End

The metal end is a vital part of any tape measure and it is important to keep it in good working order.

There are a couple of ways to protect it to ensure that every measurement you take is accurate.

- Don’t drop your tape – I know this is easier said than done and we all drop our tapes from time to time. What I have found is most of the time your tape will hit the hard ground metal end first. This bends the metal end and means your external measurements will be inaccurate. Storing in your apron is best. If you do drop it, be sure to check the end and straighten it with a pair of pliers or a hammer over a steel edge.

- Don’t let the tape retract at full speed – If you pull your tape measure blade out a long way, don’t just let it go and retract at full speed. By doing this, the metal end can hit home really hard and either bend the end or it can loosen the rivets that give the end that movement that it needs. I always suggest using your finger under the tape as a brake as your tape retracts.

The Metal End Of My Tape Is Bent?

If you still cannot get your measurements to be equal, another thing to check on your tape measure is to make sure the metal end is square to the tape and not bent. See the picture below. If it bends inwards at all then your tape measure will be inaccurate.

This usually happens from dropping your tape on a hard surface. Ensure you check this every time you drop it. I suggest putting this down on a steel edge and hitting it with the hammer to straighten or you could use a pair of pliers.

Most Useful Tips & Tricks You Never Knew About Your Tape Measure

1. Why Is There A Hole In The Metal End?

Every tape measure has a hole at the end of the metal hook. The purpose of this hole is so that you can hook your tape over a nail or screw if you don’t have an edge to measure from.

It’s called a Nail Grab!

An example of this would be if you needed to measure from partway along with a piece of timber and you didn’t have anyone to hold the end. Simply drive in a nail or screw and hook that hole over the head of the nail or screw.

2. The Edge Of The Metal Hook Is Serrated

You may also notice that most tape measures have a serrated or rough edge on the end of the hook. This is there for a reason. This is used for making a quick scribe mark on materials by rubbing this backward and forwards and it will leave a scratch or indent.

You will need to hold the blade onto the material at the desired length you need. This is very helpful for quickly gauging the length you need but it is highly inaccurate. I don’t use this feature very often but it does come in handy.

3. The Curve Of The Blade

The blade is the part of your tape measure with all the measurements on it. If you are looking to buy a new tape measure I would suggest spending a little more and getting one with a wider blade and a deeper curve.

This will mean your blade will stay straighter over longer distances and less likely to buckle and warp meaning inaccurate measuring.

As you retract the tape further and further, the curve does decrease slightly. A wider blade also means you are less likely to need a helper to hold the metal end as a stiffer wider blade will stay steady as you take your measurements.

How To Keep The Blade Clean

I strongly advise you to wipe down your blade to keep away any gum build-up. This also means it will be easier for you to read the numbers. I once did a lot of outdoor work in the rain and found that my tape started to develop rust as I didn’t clean it.

Please remember, that your tape measure is a vital tool in the workshop which you will most likely use all of the time. For this reason, it makes perfect sense to look after it well.

How To Take Very Accurate Internal Measurements

Have you ever tried to measure the internal length of the box and realized you had to curve the end of the tape and try to guess what the number should be? Well, I have 2 easier methods for you.

- Using the body of the tape – If you have a look at the side of the plastic tape body, you will notice there is a measurement on there with some arrows. This tells you how far it is between the back and front of the tape. So next time you go to measure something internally, just butt the outside of the tape against the inside of the box and read the measurement and then add on what the dimension is on the tape body. I still find this inaccurate as it is hard to read what the measurement should be but there is a better way!

- Measure from both ends – This method is much easier and so much more accurate. Just measure from one end of the box and put a mark somewhere near the middle on a round figure. Then measure from the other end to that mark. Then just add them together! Easy right, and it’s perfectly accurate.

Related

How Accurate Is A Measuring Tape?

Most tape measures found here are going to be quite accurate. In order to keep their accuracy, it is important to look after them as noted in the above article.

However, if you are looking to make 100% sure you are getting an accurate tape measure, I suggest checking what class your tape measure falls under. Tape measures usually fall under 1 of 3 categories as listed below:

- EC Class I: They are the most accurate tape measures on the market. They tend to be slightly more expensive than the average DIY tool, but are perfect for professional work where precision is not something to compromise on. The maximum error expected in class I tapes is 1.1 mm in 10 meters – 0,001 % of margin.

- EC Class II: Slightly less accurate than class one, but still significantly more precise than the average commercial tape and suitable for all uses and pockets. The maximum error expected over 10 meters total length is 2.30 millimeters – slightly more than the 0.002%.

- EC Class III: The least accurate on the scale, therefore they might be preferred where a difference of a few millimeters does not make a difference on the overall result and does not impact the stability or the safety of the project. The maximum margin of error on a 10-meter long measure is 4.60 millimeters – 0.004 % difference.

Deviation in mm over total tape length – Source

| Length | Class I | Class II | Class III |

| 2 meters | 0.30 | 0.70 | 1.40 |

| 3 meters | 0.40 | 0.90 | 1.80 |

| 5 meters | 0.60 | 1.30 | 2.60 |

| 8 meters | 0.90 | 1.90 | 3.80 |

| 10 meters | 1.10 | 2.30 | 4.60 |

FAQ’s

Why The End Hook Of The Tape Measure Is Intentionally Riveted Loosely?

The movement on the end of your tape is to account for the thickness of the metal hook. If the end did not move your measurement would read differently from an outside to an inside dimension.

Why Does The End Of A Tape Measure Wiggle?

The end of a tape measure wiggles to ensure accurate measurements. This wiggling action compensates for the thickness of the hook itself, allowing for more accurate readings and reducing errors in your woodworking or carpentry projects.