The trusty workbench is one item at the top of the list for every woodworker. I also had these same questions so I decided to put together this useful article to help make your workbench go together easier. With that being said, what is the best wood for a workbench?

Hard Maple is the best wood for a workbench due to its high density, weight, and straight-grain structure. Important factors such as availability, personal preference, cost, and the tools you have available, may influence which wood you choose.

Determining the best wood to make a workbench will depend on several factors. You will need to know your budget and what machines or tools you intend to use on the bench. Several ideal kinds of wood for the body of the table and the tabletop include pine, maple, and even plywood.

Some types of pine may even be referred to as Whitewood. See my article on what is whitewood.

I will go over the best types of wood for building your own workbench, along with the strengths and defining features of each. You want to know everything necessary before going wood shopping so that you get the best value for your money.

You can purchase them easily online or at your local home repair store. I have also answered some of the most frequently asked questions that people tend to ask when they start constructing their first workbench. Once you are done reading this page, you will be ready to buy the wood for your customized workbench.

Top 10 Best Woods For Workbench

Some of the best wood to make a workbench include the ten options listed below. I have compiled some great woods with features that make them perfect for crafting the perfect bench. Most benches are also going to have several inches of top layer material to keep the bench sturdy, flat, and capable of holding up during heavy use.

I am listing both hardwoods and softwoods, but you do not need to go for the more expensive hardwood option to get a quality product. These are not in any particular order.

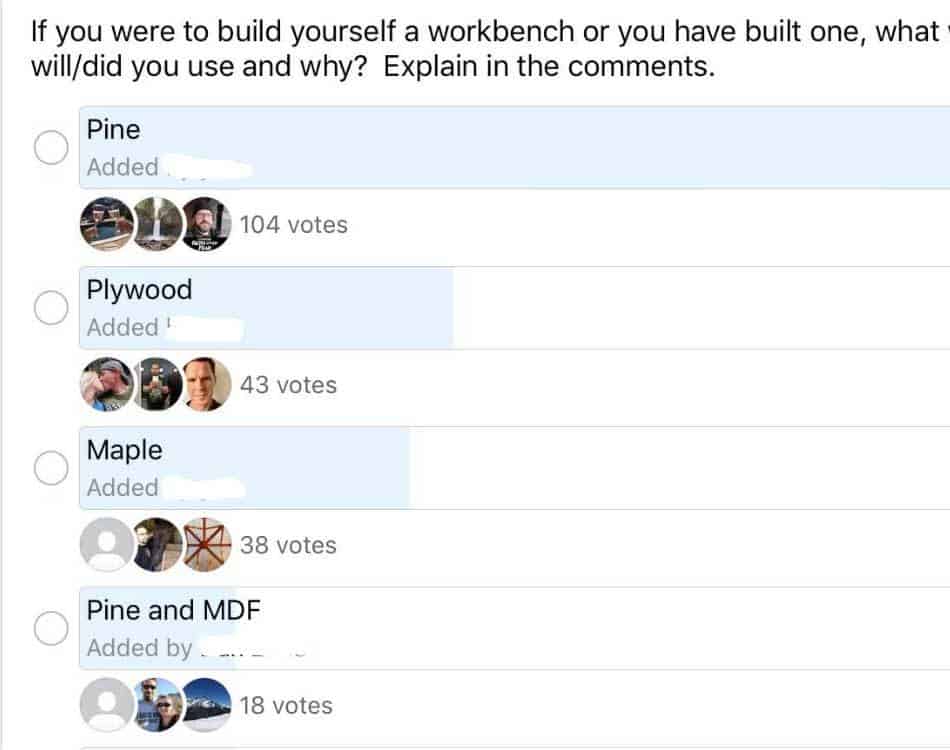

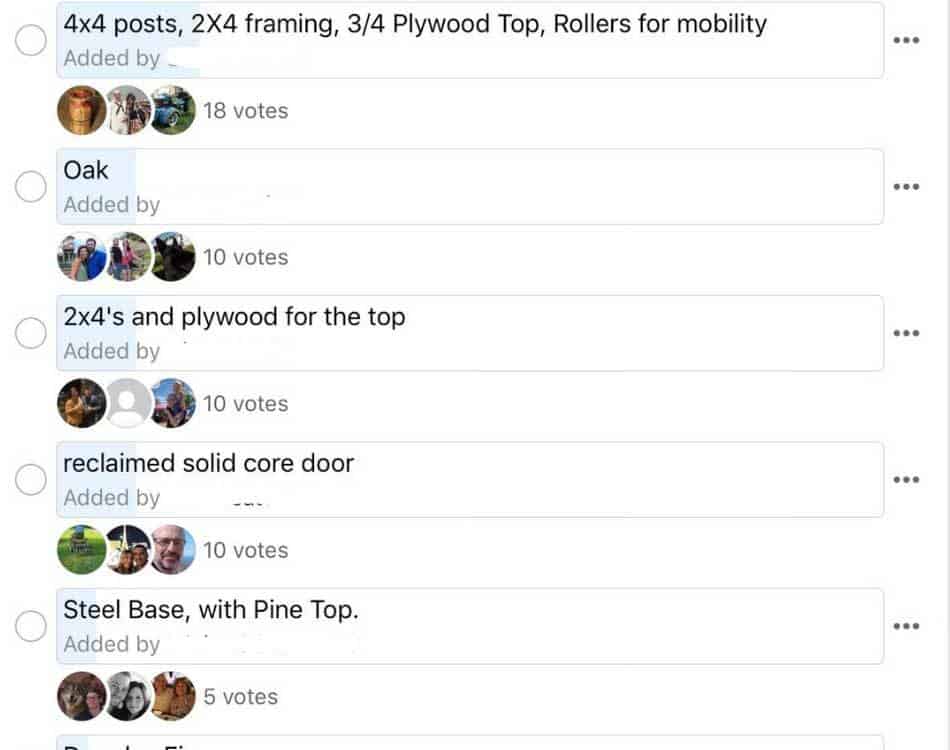

Just below these wood options is a survey I did from a popular Facebook group of woodworkers to see what they like to use. Be sure to check it out below.

To learn more about the Janka rating that we used to determine the hardness of each wood, you can read a full breakdown using the convenient scale table created by Advantage Lumber.

| Wood type | Hardness (pounds per foot) | Cost (per board foot) |

|---|---|---|

| White Pine | 380 | $2.00 |

| White Ash | 1320 | $2.50 – $7.00 |

| MDF | Varies | $1.00 – $5.00 |

| American Beech | 1300 | $6.29 |

| Yellow Birch | 1260 | $3.00 – $6.00 |

| White Oak | 1350 | $4.10 – $9.25 |

| Hard Maple | 1450 | $3.00 – $8.00 |

| Douglas Fir | 620 | $3.00 – $7.50 |

| White Poplar | 410 | $3.00 – $4.00 |

| Plywood | Varies | $2.00 – $4.00 |

1. White Pine

Wood Features:

- Medium texture

- Straight and even grain

- Light color

- Softwood

- Often used for construction and interior items

2. White Ash

Wood Features:

- Light color

- Medium or coarse texture

- Works well with machines, glues, stains, and finishes to create beautiful pieces

- Soft hardwood

- Often used in milling, flooring, and to create handmade items

3. Medium-Density Fiberboard (MDF)

Wood Features:

- More durable than plywood

- Created from resin, wax, and wood fibers

- Often used for interior and exterior building projects

- Incredibly versatile

- Very flat surface

- See my article on how to successfully screw MDF without splitting.

4. American Beech

Wood Features:

- Light color

- Works well with hand tools, machines, glues, stains, and finishes to create beautiful pieces

- Straight grain and medium texture

- Often used for making furniture, specialty items, and sports equipment

- Hardwood

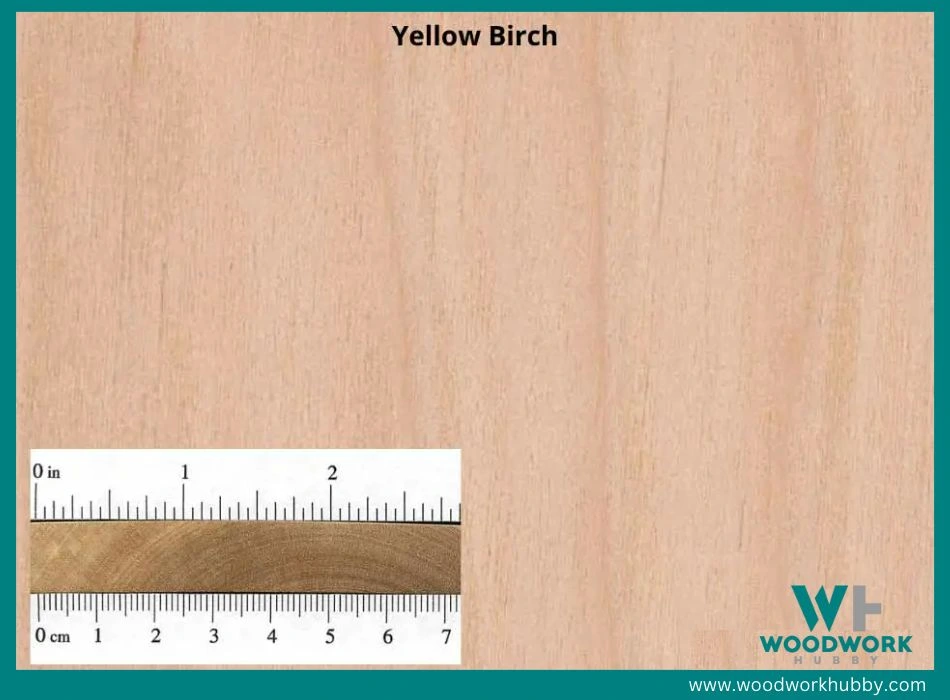

5. Yellow Birch

Wood Features:

- Light reddish-brown color

- Fine and even texture

- Wavy or overall straight grain

- Often used for trim, boxes, or specialty items

- Hardwood

- Almost any birch would work perfectly for this type of project so if you have a more plentiful local variety you can use that instead

6. White Oak

Wood Features:

- Light or medium brown

- Very durable and naturally rot-resistant

- It works well with all types of tools and machines and is easy to manipulate

- The wood may discolor if it is subjected to wet iron

- Often used in trimming, furniture, and on boats

- Hardwood

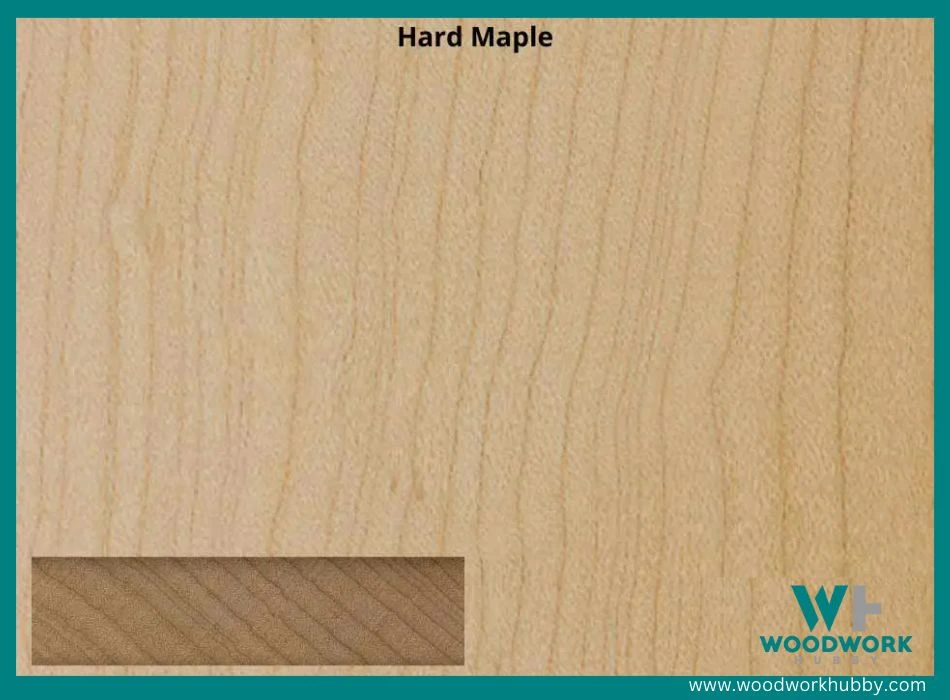

7. Hard Maple

Wood Features:

- Light in color

- Coarse and uneven texture

- Straight grain

- Hardwood

- Often used for flooring, furniture making, and cabinets

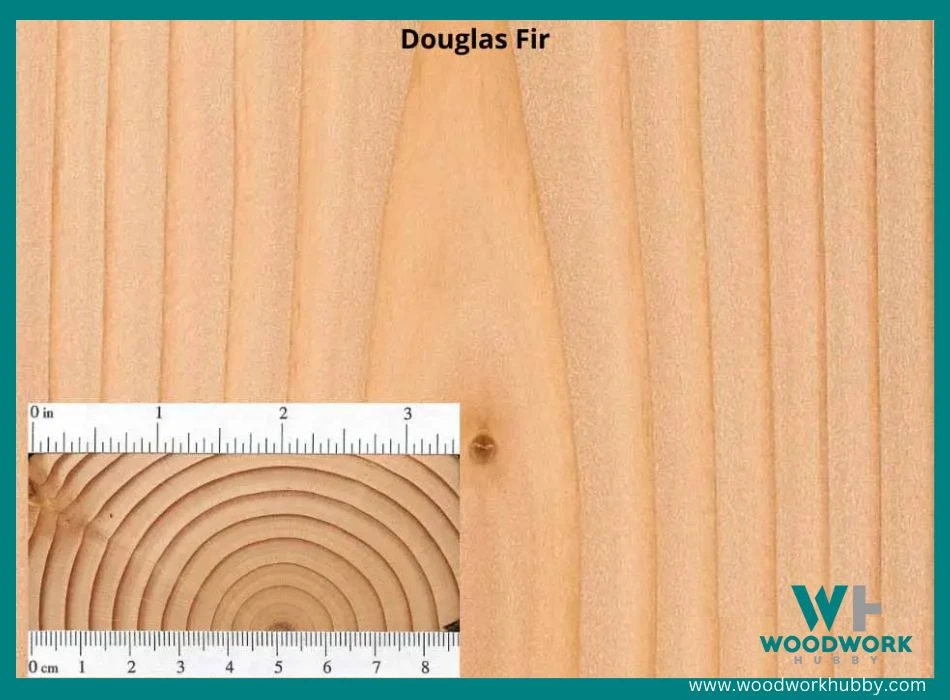

8. Douglas Fir

Wood Features:

- Light color with hints of red or cream

- Straight or wavy grain

- Medium or coarse texture

- Hardwood

- Often used for flooring, plywood, and structural repairs

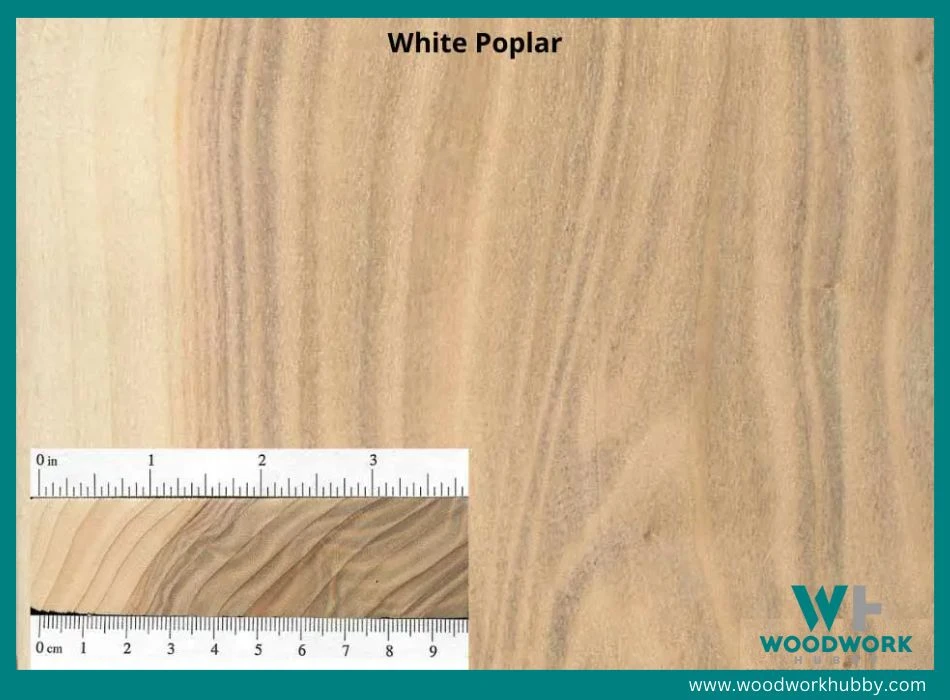

9. White Poplar

Wood Features:

- Used for a wide variety of purposes and personalized items

- Soft hardwood

- Light in color

10. Softwood Plywood

Wood Features:

- Softwood

- Light or reddish-brown in color

- Not as durable as MDF

- Often used for construction, furniture, flooring, and fencing

- Be sure to keep your plywood dry. See what happens when it gets wet here.

I Did a Survey To See What Others Use

By far the most common comment from people was:

- Whatever is easily available

- Whatever is cheapest

- Whatever you think looks the best

What Are The Workbench Types?

Here is a list of some common types of woodworking benches:

- Workbench with a vise: This type of bench typically includes a vise or multiple vises, which are essential for holding workpieces securely during various woodworking tasks.

- Cabinetmaker’s bench: These benches are specifically designed for cabinetmaking and feature a large, sturdy work surface with integrated storage compartments or cabinets for tools and materials.

- Roubo bench: Named after French furniture maker André Jacob Roubo, these benches are known for their solid construction, thick tops, and sturdy leg assemblies. They often include features like holdfasts and bench dogs to aid in workpiece clamping.

- Scandinavian or Nordic bench: This style of bench emphasizes simplicity and functionality. It usually features a thick top, and solid construction, and may include integrated storage or tool racks on the back.

- Portable or folding workbench: These benches are designed for convenience and portability. They can be easily folded or disassembled for transport and are suitable for woodworkers who need to work in different locations or have limited space.

- Power tool workbench: Specifically designed to accommodate power tools like table saws, drill presses, or routers, these benches often include integrated electrical outlets, adjustable fences, and built-in dust collection systems.

- Moxon vise bench: This bench includes a specialized vise called a Moxon vise, which is positioned higher than a traditional bench vise, allowing for easier work on dovetails and other joinery tasks.

- Carving bench: These benches are designed specifically for woodcarving. They often have a lower working height, a stable base, and features like bench hooks or holdfasts to secure the workpiece during carving.

Where Can You Purchase Wood For Your Workbench?

Once you know what kind of wood you want, then you need to find it. There are a lot of possible sources of quality, affordable wood. Below are a few places where you can purchase wood for your workbench.

See my article on where to source wood.

Home Repair Store

No matter what style of workbench you want to make, there will most likely be affordable wood at your local home repair store that you can buy.

This is a convenient option because they can cut it to your exact specifications, you can inspect the wood before purchase to ensure you are getting the most attractive pieces, and some stores will even deliver it to your doorstep.

Individual Seller

Check ads in your local paper and sites like Facebook or Craigslist to find out if anyone has posted up about extra wood they may have for sale. You might even get lucky and find some quality pieces for free.

Some individual sellers are not very familiar with the wood that they may have, so if the price seems marked up to high compared to market prices, you can usually haggle it down to a reasonable amount.

The one downside of buying from an individual seller is that you have no guarantees and you may discover that the wood is of inconsistent quality.

Online Lumber Catalog

There are hundreds of online lumber catalogs that you can look through to find the right prices and shipping for your budget. A few of the most common are listed below.

Local Lumber of Woodworking Sources

You may be lucky enough to live in a town with a mill where you might be able to get a deal for some rough-cut wood for your project. Most woodworking communities will also have information available about where to find the best local wood resources. You can check local woodshops and online forums on sites like Facebook to find out more.

Auction Site

Another place you can look at is auction sites. Sometimes when mills, woodshops, or other professional locations close down, they have leftover wood that still needs to be sold off.

You can usually get auctioned wood at a bit of a discount and in bulk, so if you want to make your workbench and have some left over for your first few projects, then this is a good option to check out.

Although there are many generic auction sites like eBay, you will usually find the best overall deal by doing a search for your state. For example, if you live in Ohio, you could search for “Ohio lumber auction” in your web browser.

Mistakes to Avoid When Building a Workbench

If you have never built a workbench before then, there are a few things you will want to avoid doing to ensure you get the best results. These are pretty straightforward but easy to forget during the moment.

- Make a Plan: the number one mistake that people make is forgetting to make a game plan. You need to know the space available and desired top space for the bench, how much money you have to spend on it, and what style you want. Without nailing down those few factors, you might end up overspending or with a workbench style that is not capable of everything you require.

- Holdfast/Dog Holes: many first-time workbench builders put in way too many holdfast/dog holes. You do not want to start with more than eight individual holes. You can always add more if you need them later. See my article explaining why workbenches have holes in them

- Leg Vises: you will also want to ensure that you do not go overboard with leg vises. A tail and face vice are all you really need.

- Complex or Unnecessary Add-Ons: there is no reason to have nifty hidden drawers or shelves that will ultimately be more trouble than they are worth. While they might look cool on paper, in reality, they can be finicky, and unnecessary, and add more weight and cost to the finished product.

- Overthinking: any aspect of the build can be thought to death and leave you indecisive and wasting time and money. Try not to overthink past the initial planning stage. If you get the basics down, there is nothing to stop you from perfecting on your finished bench down the road.

Best Wood For Workbench Legs

The best wood for workbench legs depends on several factors such as durability, stability, and availability. However, I have used and would recommend, hardwoods like oak, maple, and beech as these are often considered excellent choices for workbench legs due to their strength and resistance to wear and tear.

These woods provide stability and support to the workbench, ensuring it can withstand heavy loads and constant use. I would suggest picking one of these woods that best suit the color you would like to see if your workbench.

Best Wood For Workbench Frame

In my experience, I have found that hardwoods like oak, maple, and beech are the best choices for a workbench frame. These woods offer exceptional durability and stability, ensuring that my workbench can withstand heavy use and support the weight of my projects.

Not only are these hardwoods strong, but they also have a naturally tight grain that resists rocking from the movement of the bench during planning, etc. Overall, I highly recommend using hardwoods like oak, maple, or beech for the frame of a workbench for their strength, durability, and visual appeal.

Best Wood For Top Of Workbench

As a general rule, the same wood that is used for the base or frame is used for the top of a workbench. This is not mandatory though and you may choose to use something more cost-effective or easily replaceable.

The material you use will depend on which type of workbench you have chosen, your budget, and whether you care more about looks or functionality. Below are some material options based on those three factors.

- Most Affordable Options: beech, pine, and MDF are all affordable options that give you a variety of hardness levels.

- Highest Quality Appearance: hardwoods including pine, ash, and oak will give you a beautiful bench.

- Easiest to Purchase and Manipulate: there is a wide variety you can get from your local home repair or woodworking store, including poplar, maple, douglas fir, and the woods we beech, pine, and oak.

Why You Should Choose A Wooden Workbench Surface?

A solid wood workbench surface is probably the best option for longevity and sustainability in my opinion.

Solid wood or a wooden surface is strong and can easily be sanded or planned down when it becomes worn. This reveals a new surface to work on again.

I do like workbench tops made from MDF due to their flatness, but these do not compare to solid wood tops.

What Is The Best Plywood For a Workbench?

Birch plywood or any other that is of high quality will be suitable to use for a workbench. Choose one that is at least 1″ (25mm) in thickness or you can laminate 2 pieces together to make the frame stronger. Plywood is easy to use as it comes in sheet form.

A wrote this about using OSB or plywood for a workbench here.

However, I recommend using MDF, softwood plywood, phenolic board, and appleply. They are going to give you the stability and strength you want in a workbench without costing too much.

The top is going to be a few inches thick, so you will want to make sure whatever wood you choose can either be bought already in the right thickness or that you can easily combine layers to achieve the desired dimensions.

You may also want to read: Do You Need A Circular Saw Or Jigsaw For Plywood?

Does Medium-Density Fibreboard (MDF) Make a Good Workbench Top?

MDF is a great top for a workbench as it is flat, stable, easy to use, and can be replaced when the old one wears out. It can also be bought in varying thicknesses which is important to the strength of your top.

With that being said, MDF is a personal choice so I have listed some other pros and cons that you may wish to consider before running out and buying some.

How do you pocket hole MDF? I explained how to do this in my complete guide on pocket holes in MDF.

Pros:

- Affordable

- You can find it anywhere

- It can be easily combined in layers to reach the desired top thickness

- Very smooth surface and even texture

Cons:

- MDF is water absorbent, meaning that it will soak up any liquid that comes in contact with it, which can lead to unsightly discoloration and bumps in the surface over time.

- Any holdfast holes are going to probably have at least a little noticeable fraying around the edges. You can diminish some of this appearance during the finishing process, but over time, you may notice that the holes show signs of wear and frayed fibers.

- Is prone to splitting when screwing but I wrote this article on how to overcome this problem

FAQs

Now that you know the best wood to make a workbench, there are a few other considerations to keep in mind. Below are some frequently asked questions about creating a workbench and the materials that you may want to use.

What Kinds of Workbenches Are There?

You will have to choose what type of workbench you want to build before you can decide on the wood. There are pros and cons for each, but ultimately it is going to come down to what kinds of projects you intend to use it for in the long run.

Some people prefer to start from scratch and make an entirely original workbench, while others enjoy working from a generic pattern. Below are the most common types of workbenches and their primary characteristics.

- Woodworking Bench: a typical workbench for woodworking is going to have four legs, a shelf, dog/holdfast holes, vises, and sometimes an additional built-in tool. The top is usually a few inches thick, at least to provide a strong, flat surface for working. You can make this bench out of almost any wood.

- Cabinet Maker Bench: what sets a cabinet maker bench apart from your typical woodworking bench are the drawers and additional shelves to hold all the tools of the trade. You will want to take your time if you are making one of these, and it will require additional materials, so you do not want to choose a wood that will be too expensive or difficult to get in large quantities.

- Simple Backboard Bench: a backboard bench is by far the easiest one to build. It has a tabletop, backboard for storing your tools, and a shelf underneath. You can add on a vise, but for the most part, it is a large table for working on smaller DIY projects. This can be made from pretty much any wood.

- Portable Bench: if you tend to do smaller projects around the house or in the field, then a sturdy portable option might be right for you. They usually fold down to a size that will easily fit in a trunk for transport. There are many designs to choose from, and you can go intricate or make a straightforward folding workbench with no bells or whistles. You will want to use woods that are not too heavy.

What Additional Accessories Can You Add To Your Workbench?

When you are adding DIY tools, additional storage features, or other items to your workbench, you want to make sure you do not miss out on the following useful accessories.

- Magnetic strip for storing tools

- Portable and lighter benches can benefit from having castor wheels on the legs

- Built-in power strip

- Clamp track along the edge

- Various hooks for storage and attaching cords or other tools

- A light source of some kind like an adjustable lamp to help you get light where you need it during projects

How Thick Should You Make Your Workbench Top?

As a general rule, 2.5″ – 3″ inches (62.5mm – 75mm) is the ideal thickness for a workbench top. This thickness is usually achieved by gluing together layers of wood and providing the strongest top.

You do not want your workbench top to be too thick. Usually, your workbench top is made from the same material as the bench frame. However, some other common materials for workbench tops include the following.

- Phenolic Board

- Softwood Plywood

- Marine Grade Plywood

- Baltic Birch

- Medium-Density Fibreboard (MDF)

- Appleply

I highly recommend MDF as the top material because it is durable, very flat, and easy to layer to reach your preferred thickness. There are a few downsides to using it, though, and you can learn more about them in the section below, where I go over the pros and cons of MDF. See my tips on how to screw MDF without splitting.

Should There Be An Overhang Around The Edges Of The Workbench Top?

A common overhang is 4″ inches (100mm) which be helpful if using clamps to hold things down although this is entirely at your discretion.

The width of your workbench top should be taken into account when you measure your workspace to make sure you have enough room to move around if you are adding several inches to three of the sides.

Is Pine Too Soft For A Workbench?

Pine may not be the best choice for a workbench that requires durability and stability. Due to its softer nature, pine is more prone to denting, scratching, and general wear and tear, especially when subjected to heavy use or pressure.

I have found that mortise and tenon joints in a workbench have sometimes loosened due to the softwood fibers compressing.

How Thick Should Workbench Legs Be?

As a general guideline, workbench legs are commonly made with lumber ranging from 2 to 4 inches (50-100mm) in thickness.

Thicker legs provide greater stability and strength, making them suitable for heavy-duty applications or workbenches that will support substantial weight. Thinner legs, on the other hand, may be suitable for lighter projects or workbenches that require more mobility and flexibility.

What Is The Best Wood For A Butcher Block Workbench?

One of the most commonly used woods for butcher block workbenches is hard maple. Hard maple has a tight grain structure and is incredibly hard, making it resistant to cuts, scratches, and dents. It also has natural antimicrobial properties, which are crucial for maintaining a hygienic work surface.

Another excellent option is beech wood, which shares similar qualities with hard maple, including its hardness and resistance to moisture.

Both hard maple and beech wood are preferred for butcher block workbenches due to their durability, ability to withstand heavy use, and ability to provide a safe and sanitary surface for food preparation.