No workshop can be without the trusty tool called a jigsaw! They are invaluable for a lot of jobs but can also be frustrating at times. One question I get asked all the time from my friends is why does my jigsaw blade bend?

A jigsaw blade will bend due to the following reasons:

- The Blade Is Blunt Or Dull

- Using The Wrong Type Of Blade

- Trying To Cut A Steep Curve

- Cutting Too Fast

- Timber Is Too Thick

- Pushing The Jigsaw

- Blade Guides Are Worn

- The Base Of Jigsaw Is Not Square

- Using A Straight Edge

- Using the Orbital Setting

In my cabinet-making days, I used a jigsaw every day to cut kitchen sinks into benchtops that were 35mm (1.4″) thick. I had plenty of experience with a jigsaw and yes I also had plenty of times where the blade would bend.

I will go over each of the 10 reasons above in detail and explain why your jigsaw blade bends and how you can fix it.

Why Does My Jigsaw Blade Bend?

So what do I mean by “bend” in this article? When I refer to bending it is the sideways movement of the blade during a cut. If your blade bends, your cut will not be 90 degrees to the face meaning there will be a lot more work for you to prepare the edge afterward.

Bending can be very frustrating as from the top of your timber workpiece, the cut looks as though you have followed the line. When you turn your workpiece over, you will discover the cut is out of line and wavy meaning the blade has bent during the cut.

Keep on reading as I explain all the factors in detail which will stop your blade from bending again!

Be sure to check out my article on why does my jigsaw jump?

and also, why your jigsaw does not cut straight.

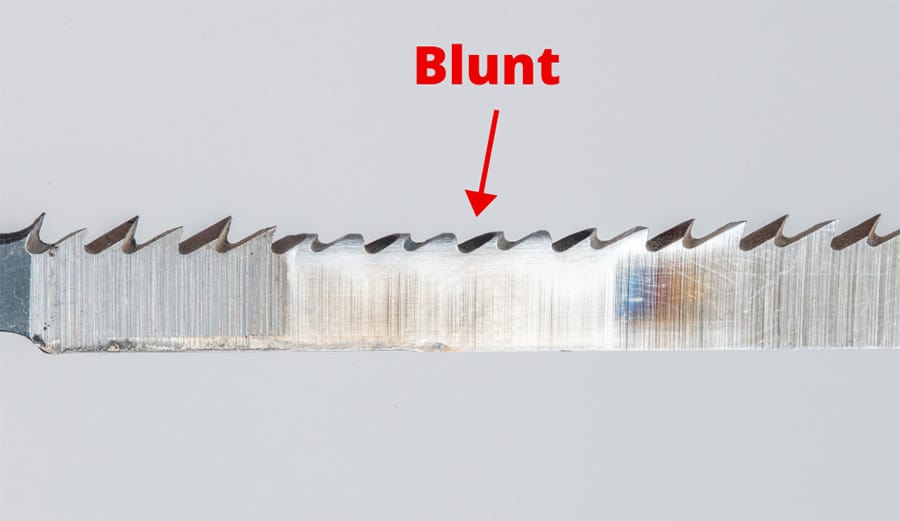

1. Is Your Blade Blunt Or Dull?

The first thing you need to check and one of the biggest causes of your blade bending is a blunt blade.

If you have used your blade a few times and the sides of it are looking worn and the tips of the teeth aren’t as sharp as they used to be, then it’s time to swap blades.

A sharp blade will cut and remove the wood fibers quicker and with less effort which will always result in a straighter cut. I always recommend swapping blades very often as this will get the best results from your jigsaw.

2. Are You Using The Wrong Type Of Blade?

When it comes to jigsaw blades, there are lots of different types to choose from. The wrong type of blade could be contributing to why your blade is bending during the cut.

For example, if you are trying to cut timber that is over an inch thick and the blade you are using has a lot of teeth on it, the blade might be generating a lot of heat while you are cutting because it can’t expel the wood fibers quick enough.

A jigsaw blade will bend if you try to cut timber that is too thick. Find out here if a jigsaw can cut a 2×4?

Excess heat on a blade will mean it is more likely to bend compared to one that stays cooler. If you are getting any heat or smoke from the blade, stop and change it over.

I have created the below table to help you decide which blade you should use for which cut.

| Blade | Type | For Cutting | Notes |

| Bosch T101AO | HCS (High Carbon Steel) | Softwoods Plywood Laminated Boards | Cuts from 5-20mm For tight curves |

| Bosch T101A | HSS (High Speed Steel) | Metal Copper Aluminium Perspex | High Abrasive Resistance |

| Bosch T101B | HCS (High Carbon Steel) | Softwoods Hardwoods Plywood | Cuts from 3-30mm |

| Bosch T101BR | Reverse Cut (Cuts downwards) | Softwoods Hardwoods Plywood Chipboard | Cuts 40mm |

| Bosch T111C | HCS (High Carbon Steel) | Softwoods Hardwoods Plywood Chipboard | Cuts from 5-50mm |

| Bosch T118GFS | BIM (Bi-metal) | Stainless Tough plate materials | Cuts from 0.5-1.5mm |

| Bosch T119B | HCS (High Carbon Steel) | Softwoods Plywood Chipboard | Cuts from 5-15mm |

It’s also important to note here, you can buy jigsaw blades that are thicker than most. This extra thickness can sometimes help eliminate the blade bending during a cut.

How Much To Spend On Blades?

This is where the old saying comes in, “You only get what you pay for”. The same rule applies to jigsaw blades. I always suggest you buy the best blades you can for your machine.

Don’t skimp on a few bucks here. A very good quality blade is likely to give you a far superior cut. This will mean you won’t get a temper (LOL!) and you will save time but not have to sand or clean up the cuts as much.

I will always buy the best blades and get a few of them so when one starts to get dull, I can change it out.

3. Are You Cutting A Steep Or Sharp Curve?

Whenever I attempt to cut an excessively sharp or steep curve especially on timber over 20mm thick, I usually get some bend from my blade.

This bending will get 10 times worse if you are using the wrong type of blade. For sharp or tight curves I recommend the Bosch T101AO as seen in the table above.

For any sharp curves, you should be buying a blade that is narrow. This means the back edge of the blade won’t bind on the back of the cut.

The trade-off to this is a narrower blade can tend to bend more easily than a wider one.

Right blade but it still bends? Try taking your time during curved cuts and using several shallower cuts to clear a path for the blade. Eventually, with a good sharp blade and a slow rate of cut, you will be able to cut without the blade bending.

4. Are You Cutting Too Fast?

This seems to be one of the more likely causes of your jigsaw blade bending. You should always take your time and let the blade and the jigsaw do the work.

If you find you are having to push on the jigsaw to make it cut, then you will have one of these 3 problems:

- The blade is blunt

- Wrong blade for the type of cut

- You are rushing the cut

Once you have fixed these issues, just let the jigsaw do the work. The only thing your hand should be doing is guiding it in the right direction.

Try this next time and I can assure you, your blade will bend less!

Try to keep the dust down with one of these tested shop vacs.

5. The Timber Could Be Too Thick?

How thick is too thick? Well, that depends on the length of blade you are using but generally, anything around 40mm in thickness and over is becoming a big ask for a jigsaw blade not to bend.

Yes, it will cut but more often than not your blade will bend at this thickness. This is because the distance from the blade guides to the end of the blade is much greater than it is while cutting something that is 20mm thick.

Because the very tip of the blade has nothing to guide it, it may start to wonder and take the path of least resistance through the timber fibers.

For any timber 40mm thick and over I would recommend using a bandsaw as it will leave a much cleaner and straighter cut. If you don’t have one, maybe try buying a thicker and longer jigsaw blade and take your time with the cut.

6. Don’t Push The Jigsaw

I know this seems like a funny thing to say as you almost always need to push it a little to make it cut. What I am referring to is how hard you are pushing it.

I know most people tend to force the jigsaw through the wood. When we do this, more often than not, we are actually putting some sideways pressure on the machine.

When we put sideways pressure on the jigsaw, it can tilt ever so slightly which will cause the blade to cut out of square or bend. As we make longer cuts, this bending continues to compound until our blend can be seen bending quite badly.

Now I know this one is not a major, but in the hands of inexperienced users, this can be very common. Just a little tip to pay attention to next time you are cutting.

7. Check Your Blade Guides

What are the blade guides you ask? They are the 2 small rollers or guides that are just above the jigsaw base that the blade runs between.

The purpose of the blade guides is to keep the blade straight and provide support to the back of the blade during a cut. All decent jigsaws should have these guides or rollers.

I suggest checking these guides to ensure the blade fits snugly between them and that you don’t any excessive wear or play here. If they are worn your blade can wander during a cut which can lead to the blade bending or leaning over in the timber.

A good set of blade guides is critical to the performance you will get from the machine and your cut. Please consider replacing them if they are worn. If you are unsure if your guides are ok, please take the jigsaw to your local tool specialist and they will inspect it for you.

Grab some of these high quality jigsaw blades that I use and recommend.

8. Is Your Jigsaw Base Square?

Just about all jigsaws have a tilting base that can enable angular cuts. Often this titling base can be out of square with the blade meaning your cuts will not be square.

Sometimes starting a cut at an angle is enough to make the blade start bending or wandering given the right conditions.

I often see woodworkers set their tilting base thinking it will be ok without ever really checking it for square. Use a small square to check that the base is right.

Also, a base may become loose over time from the constant vibration. Check the little lug screw under the base to make sure it’s tight and everything is as it should be.

9. Do You Use A Straight Edge When Cutting?

I often see woodworkers trying to cut a piece of timber, and they insist on using a straight edge for the base to run along so that they get a straight cut.

This practice should not be implemented when using a jigsaw. If you want to make straight cuts, you should be using a circular saw.

A jigsaw should mainly be used to make curves cuts. Why should you not use a straight edge? When you cut with a jigsaw you normally have to make micro-adjustments left and right to keep the blade on a straight path.

A straight edge prevents you from making these adjustments. If following a straight edge, the blade could continually start to cut its own course and eventually lead to the blade bending.

Another reason not to use a straight edge is the blade may not be running parallel with the base. Because jigsaws are not meant for long straight cuts, the blade is often fractionally on a different line to the edge of the base.

10. Do You Use The Orbital Setting?

Haha, I hear you asking, what is the orbital setting? This can be referred to in other names, but the orbital setting is the small switch on the side of a jigsaw that changes the blades up and down movement into increasing levels of elliptical motion.

Most jigsaws have 3 levels of orbiting. This simply adjusts the amount that the blade moves in and out while cutting. The highest setting of orbiting while cutting thicker timber can usually lead to your blade bending.

I would try to use the straight up and down setting for any cuts in thick stock.

More On The Orbital Setting

Let me explain more about how this orbital setting works.

When the blade moves in a downwards motion, the blade stays straight on a vertical plane. Then as the blade comes up it also moves outwards slightly depending on which setting you have used.

So you see this kind of circular motion of cutting gives a more aggressive cut and does take some more skill to control.

Don’t be scared of using it though as it really can make cutting a lot easier but it can also lead to bending of the blade.

Why Use The Orbital Setting?

By increasing the amount the blade cuts outwards, you can get more aggressive and faster cuts from your blade. This can be very handy to use when you start cutting timber that is over 20mm in thickness.

While the orbit settings are great for rough cutting, they have their own set of drawbacks. These are listed below:

- More tear out

- Less control

- Higher Vibration

While I often use an orbital setting for every cut, make sure you vary the strength of it as this can sometimes lead to the blade bending in a cut.

If you require accuracy in a cut, I recommend switching the orbit action to very low or off.

Time To Talk Dirty

I know woodworking can be a great hobby to get into, but you need to sometimes check over your tools to make sure you are using the right tools for the job.

For example, if you are wanting to make a lot of curved shapes in woodwork and you will be using your jigsaw often, I suggest you get a good quality machine.

Now I’m not trying to get you to spend your hard-earned money. I’m simply explaining that rubbish tools will give you rubbish results. A jigsaw has a lot of moving parts and needs to be of decent quality.

More often than not, this is why I find people’s jigsaw blades keep bending. I used to own a cheap jigsaw and no matter what blade I used or how I cut, the blade would bend over to some degree.

Let’s face it, a jigsaw is one of the most common tools in any woodworking shop. While you can save on cheaper tools here and there, I feel like a jigsaw is something that must be of good quality to get good results.

Now you don’t need to go buying the best Festool jigsaw you can find although I have nothing against Festool. I would like to show you how to get a good quality jigsaw without spending a fortune.

Here is the jigsaw that I use that gives me amazing results.

Conclusion

As you can see there are many reasons why your blade may be bending and more often than not, a few of these factors combined will be the cause.

Go through and check all of these points and I’m sure you will be pleasantly surprised with how well your do with your next cut with your jigsaw!