If you’ve recently purchased a table saw, you may find yourself puzzled over whether its table saw blades are reverse threaded. Believe me; I’ve been there! This mystery led me to dig deep and uncover the facts about the threading direction of table saw blades.

In this article, we’ll navigate the world of table saw blade threads together, explaining what it means for a blade to be reversed threaded and how this impacts usage. Stick around if you’re keen on understanding your power tool better!

Key Takeaways

- Table saw blades can be reverse threaded, meaning they rotate counterclockwise instead of clockwise.

- Reverse threading provides a secure grip and helps in fastening the blade onto the table saw for safety and firm attachment.

- Changing a table saw blade requires proper tools, including wrenches, and following necessary safety precautions like unplugging the saw before beginning.

Understanding Reverse Threaded Blades

A reverse-threaded blade refers to a table saw blade that rotates in the opposite direction compared to standard threads, counterclockwise instead of clockwise.

Video showing how to change a table saw blade

What Does Reverse Threaded Mean?

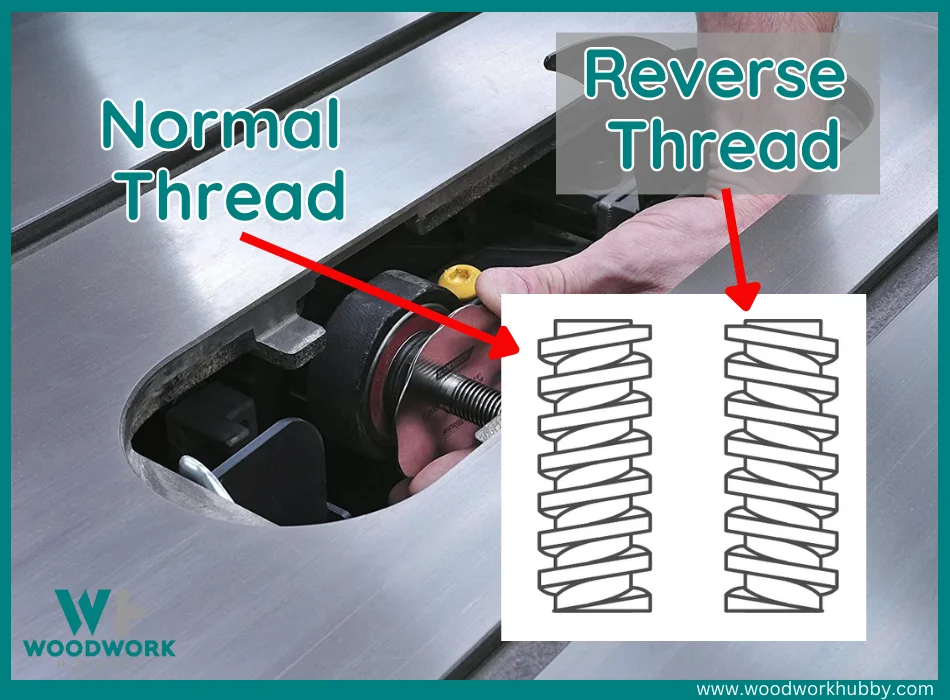

Reverse threaded means the thread turns the opposite way. In other words, you tighten it by turning to the left and loosen it by turning right. This is different from standard threading where you turn right to tighten and left to loosen.

When talking about table saw blades, they have reverse threads for a secure grip. They rotate counterclockwise which helps in fastening or securing them better onto your table saw.

After many years of using table saws, I have come up with the best table saws under $1500. Be sure to see which ones I have included.

Unlike miter saw blade bolts and right-handed circular saws that are not reverse threaded, a table saw uses this method for safety and firm blade attachment.

Importance of reverse threaded blades

Reverse threaded blades are key for table saws. They spin the other way than normal threads. This is because the nut would undo itself as the blade spins if a regular thread direction was used.

If you can tell the difference between a standard thread and a reverse one, it will be much easier to take care of your tools.

Not all tools use reverse threading though! Miter saw blade bolts have left-hand threading, which is the usual kind. The same goes for lawn mower blades – they only look reverse-threaded because some nuts on the mowers are made that way!

So don’t get mixed up when dealing with different types of equipment or you could mess up their care and maintenance!

How To Tell If The Table Saw Is Reverse Threaded?

You can usually tell if a thread is reversed by closely looking at the threads. A reverse thread means the nut will tighten by turning to the left and loosen by turning to the right.

The image below shows the difference between the 2 threads.

See the table saws I recommend as being the best beginner table saws. I wrote this article outlining which one I think is best and why.

How to Change a Table Saw Blade

To change a table saw blade, first, make sure the saw is unplugged and the throat plate is removed. Then, raise the blade all the way up and use a wrench to loosen the nut holding the blade in place.

Carefully remove the old blade and replace it with the new one, making sure it is properly aligned. Finally, tighten the nut securely and reattach the throat plate before plugging in and testing out your newly installed blade.

Video on how to change a table saw blade

A step-by-step guide to changing the blade

Changing a table saw blade needs focus and the right steps. Here is a guide to help you do it:

- First, unplug your table saw. It’s easy to forget this step, but it’s very important for your safety.

- Get your tool kit ready. You will need a wrench or two.

- Next, remove the blade guard. This part keeps you safe when the saw is on.

- Now, find the locking mechanism on your saw and lock it down. This step stops the blade from moving.

- Use your wrench to loosen off the blade nut which holds the blade in place.

- After loosening the nut, you can remove the old blade from its spot.

- Once removed, inspect your new blade before installation.

- After inspecting new blade install it in place of old one and tighten back up with nut using wrench.

Tools needed for the process

To change a table saw blade, you will need the following tools:

- Two wrenches: One wrench is used to secure the arbor, and the other is used to loosen the nut.

- Arbor: The part of the table saw that holds the blade.

- Nut: The nut holds the blade in place on the arbor.

- Washer: A washer is placed between the nut and the blade for added stability.

- Blade: The cutting tool that is attached to the arbor.

Different Types of Table Saw Blades

There are several different types of table saw blades, including Flat Top Grind (FTG) Blades, Alternate Top Bevel (ATB) Blades, Combination (ATBR) Blades, and Triple Chip Grind (TCG) Blades.

Video on how to change the blade on a DeWalt saw

Flat Top Grind (FTG) Blades

Flat Top Grind (FTG) blades are a type of table saw blade designed for ripping through wood quickly. These blades have square-shaped teeth, also known as Rakers, with flat and square top edges.

Be sure to reveal the truth on can table saw blades be sharpened.

FTG blades have fewer teeth, larger gullets (the spaces between the teeth), and a steeper rake angle, which allows them to cut fast across long distances. They are specifically designed for cutting along the grain of the wood, making them ideal for rip cuts.

Understanding the different types of table saw blades and their tooth designs is important for achieving accurate and efficient cuts in woodworking projects.

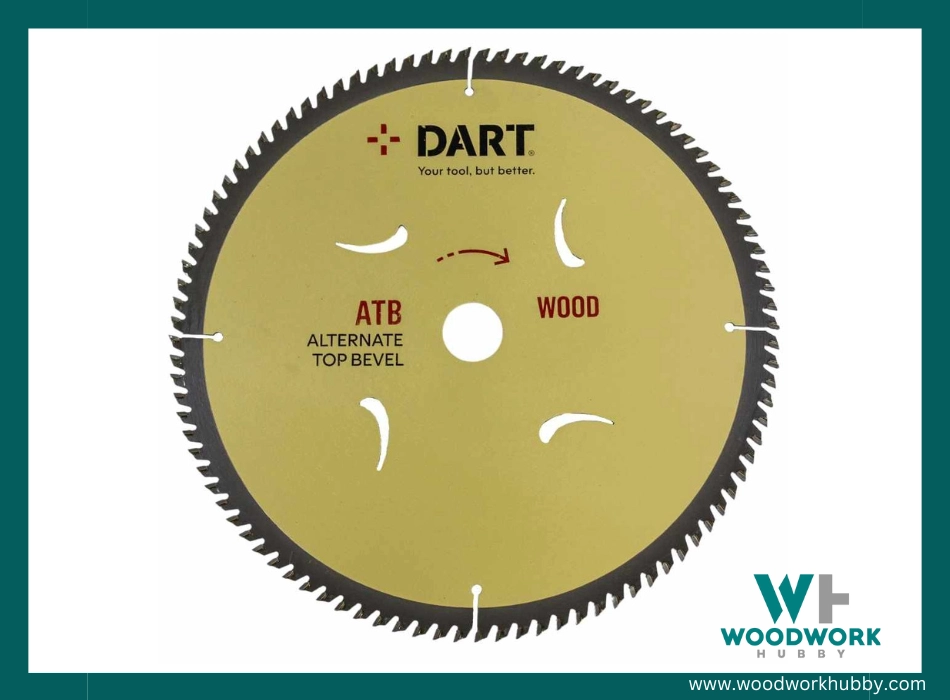

Alternate Top Bevel (ATB) Blades

ATB blades are a type of table saw blade that is really useful for cutting at different angles. They have teeth that are angled across the top edge, which helps them make cleaner cuts.

These blades are great for cross-cutting applications because they can cut through the grain smoothly. Compared to other types of blades, ATB blades give you smoother cuts, making your projects look even better.

Combination (ATBR) Blades

Combination blades, also known as ATBR blades, are a type of table saw blade that combines the features of Flat Top Grind (FTG) and Alternate Top Bevel (ATB) blades. These blades have 50 teeth arranged in sets of five.

Some of these blades are vital when making dado cuts. I’ve compiled a list of the best table saws for dados.

Each set consists of four ATB teeth followed by one raker tooth. This tooth arrangement allows combination blades to be used for both ripping and crosscutting tasks. That’s why they are popular among woodworkers for their versatility.

Whether you need to make long cuts with the grain or smooth cuts across it, combination blades can handle both effectively.

Triple Chip Grind (TCG) Blades

Triple Chip Grind (TCG) blades are a type of table saw blade that is specially designed for cutting heavy and dense materials. These blades are commonly used for cutting non-ferrous metals, such as aluminum, as well as composite materials.

One of the key features of TCG blades is their unique tooth geometry. They have alternating flat top grind and chamfered trapezoidal shape, which helps them produce clean and chip-free cuts.

This makes them ideal for tasks that require precision cutting. Additionally, TCG blades are known for their durability and ability to withstand the demands of cutting dense materials.

Tips and Safety Measures for Handling Table Saw Blades

Ensure your safety by using proper protective gear, unplugging the saw before changing blades, securing the blade tightly, and regularly maintaining and cleaning it. To find out more about how to handle table saw blades safely, keep reading!

Using proper protective gear

When using a table saw, it is essential to wear the right protective gear. This includes safety glasses or goggles with side shields and a face shield to protect your eyes from flying debris.

Additionally, industrial quality ear protection should be worn to safeguard your hearing from the loud noise of the machine. Personal protective equipment plays a crucial role in ensuring your safety while operating a table saw.

Remember, always prioritize your well-being by wearing the appropriate protective gear when using this powerful tool.

Ensuring the saw is unplugged

Before you start changing the blade on your table saw, it’s important to always make sure that the saw is unplugged. This is a crucial safety measure to prevent any accidents or injuries while handling the blades.

By confirming that the power source is disconnected, you are following safety regulations and prioritizing your well-being. Always double-check and be certain that the table saw is not connected to power before you begin working on or replacing the blades.

Safety should always come first when dealing with table saw blades, so take this extra step to ensure a safe working environment.

Properly securing the blade

To safely handle table saw blades, it is essential to properly secure the blade. This means ensuring that the blade arbor nut is tightened securely using a nut wrench. By doing so, you can prevent any accidents or injuries caused by a loose or dislodged blade while operating the saw.

When securing the blade, always remember to stand to the side of the saw blade rather than directly in front of it. This position helps minimize the risk of injury from kickback, which occurs when wood gets caught and forcefully thrown back towards you by the spinning blade.

Taking these steps to properly secure the blade not only promotes safety but also ensures efficient and precise cuts. Remember to regularly check and tighten the arbor nut before each use to maintain a secure connection between the tool and its rotating component.

Regular maintenance and cleaning

To ensure the best performance of your table saw blades, regular maintenance and cleaning are crucial. By keeping your blades clean and free from dirt, debris, and contaminants, you can maintain their efficiency in woodworking operations.

To clean the blades, I recommend using a stiff-bristled brush or cloth along with a water-based cleaner or mild detergent. This will help remove any built-up residue and keep the blades in optimal condition.

It’s also important to regularly check for any signs of damage or dullness and address them promptly to ensure safe and effective cutting. Remember that proper blade maintenance is essential for both safety and efficiency in your woodworking projects.

Conclusion – Are Table Saw Blades Reverse Threaded?

In conclusion, table saw blades can indeed be reverse threaded. This means that they rotate in the opposite direction of standard threads. It’s important to pay attention to the tilt of the blade and follow proper safety measures when handling and changing table saw blades.

By understanding how these blades work, we can ensure safer and more efficient woodworking experiences.

FAQs

1. Do table saw blades have reverse threading?

Most table saw blades have reverse threading meaning they tighten by turning to the left, not the right.

2. How do I remove a table saw blade?

To remove a table saw blade, you need to use a wrench to loosen the arbor nut by turning it clockwise it most cases. Check the threads before starting.

3. Can I install a new table saw blade myself?

You can install a new table saw blade yourself by following the manufacturer’s instructions and ensuring that the arbor nut is securely tightened.

4. What should I do if my table saw blade gets stuck?

If your table saw blade gets stuck, turn off the power and wait for it to completely stop spinning before attempting to remove any obstructions or free the blade.