Unsure if your table saw can handle cutting metals? You’re not alone, I found myself asking the same question not long ago while trying to rip some aluminum. Through solid research and hands-on experience, I can answer that age-old question, Can a table saw cut metal?

Key Takeaways

- A table saw can cut certain metals like aluminum and soft metals like brass.

- When cutting metal with a table saw, it’s important to match the blade to the type of metal being cut for clean and easy cuts.

- Adjusting the cutting speed is crucial when cutting metal on a table saw to ensure better performance without damaging the blade.

- Taking safety precautions such as wearing protective gear, using push sticks or blocks, setting up a blade guard, and having kickback pawls in place is essential when working with a table saw.

Factors to Consider When Cutting Metal with a Table Saw

When cutting metal with a table saw, it is important to consider several factors such as matching the blade to the type of metal being cut, adjusting the cutting speed accordingly, and ensuring proper safety precautions are taken.

Video showing cutting metal on a table saw

Matching the blade to the type of metal

The blade you use in your table saw matters a lot when cutting metal. Using the right blade makes cuts clean and easy. You should know the type of metal first before picking out a blade.

I put together a list of the best table saws under $1500. You can read what I wrote here in my article.

This way, you can choose either High-Speed Steel (HSS) or tungsten carbide blades. These are top picks for any metal-cutting job. Also, do not forget to match the strength of the blade with that of your metal.

This will keep your saw from breaking or bending its blades during the cut!

When changing table saw blades which way do you turn the nut to loosen it? I explain the answer here in my article Are table saw blades reverse threaded?

Adjusting the cutting speed

The speed of my table saw needs changes for cutting metal. I make it faster than usual. This way, the blade works better with the hard metal. It’s an important part of cutting metal on a table saw.

But, too fast can hurt the blade. The high speed wears out my carbide saw blade quicker. So, I like to keep my speed low when working with metals. This prevents damage and keeps my tool lasting longer.

Ensuring safety precautions

I always put on safety gear before using a table saw. This includes goggles, gloves, and protective clothing. These items guard me from any bits of metal that might fly off during cutting.

It’s also critical for me to use push sticks or blocks. They keep my hands away from the sharp blade and reduce the risk of getting hurt.

Next is setting up a blade guard on my table saw. This step keeps me safe by blocking accidental touch with the moving blade. Kickback pawls are another part I make sure to have in place.

They stop pieces of cut metal from shooting back at me when I’m working, which can lead to bad accidents. An example of the wrong procedures can be found in my article why is the table saw burning wood?

Tips for Cutting Metal with a Table Saw

When cutting metal with a table saw, it is important to select the right metal cutting blade, watch for kickback, and use a cut-off block for stability.

Video showing how to cut non-ferrous metals on a table saw

Selecting the right metal cutting blade

When cutting metal with a table saw, it’s important to select the right metal cutting blade. There are different types of blades designed for cutting various materials, and you need one specifically made for cutting metal.

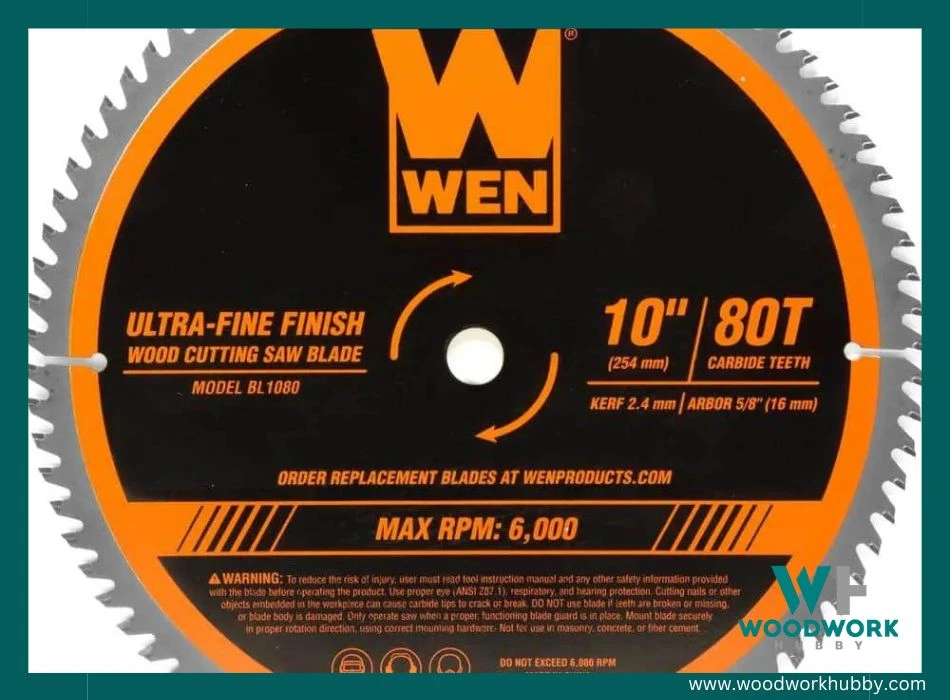

For most metal-cutting tasks on a table saw, High-Speed Steel (HSS) or tungsten carbide blades are recommended. These blades have sharp teeth that can cut through metal effectively.

Cutting metal can dull your blade quickly with regular use. Discover the secrets surrounding can table saw blades be sharpened? I did some trials and here is what I found.

When working with sheet metal, it’s best to use a carbide-tipped blade with at least 80 teeth. This type of blade ensures clean and precise cuts on thin materials like sheet metal.

Watching for kickback

Kickback is a serious hazard when using a table saw, even when cutting metal. It happens when the blade pushes the material back towards you unexpectedly.

This can be really dangerous! Metal cutting blades on portable table saws are especially risky because they can throw chips back at you.

To stay safe, always watch out for kickback and take precautions to prevent it. Use a riving knife (a safety device that keeps the workpiece from pinching the blade) and a push stick to help reduce the risk of kickback.

Safety should always come first!

Using a cut-off block for stability

When cutting metal on a table saw, it is important to use a cut-off block for stability. This helps prevent kickbacks and keeps the metal steady during the cutting process. It is recommended to clamp the cut-off block securely to the table to ensure it doesn’t move while cutting.

If you are still looking for a great beginner table saw, be sure to read up on the ones I have recommended.

By using a cut-off block, you can have better control over your workpiece and reduce the risk of accidents or injuries. So, make sure to always use a cut-off block when cutting metal on a table saw for added stability and safety.

Conclusion – Can A Table Saw Cut Metal?

Yes, a table saw can cut metal, including aluminum and soft metals like brass. But there are important factors to consider and safety precautions to take. Choosing the right blade, adjusting the cutting speed, and using a cut-off block for stability will help you achieve clean and smooth cuts.

While it is possible to use a regular table saw with the correct blade for cutting metal, industrial metal cutting table saws and specific blades are available for more heavy-duty tasks.

Remember to always prioritize safety when working with any type of material on a table saw. So go ahead and give it a try!

FAQs

1. Can a table saw cut metal?

A table saw is not designed to cut metal. It is primarily used for cutting wood and other soft materials.

2. What tools are recommended for cutting metal?

For cutting metal, tools such as an angle grinder, hacksaw, or plasma cutter are commonly used.

3. Why can’t a table saw be used to cut metal?

Table saws have specific blades designed for cutting wood fibers, and they are not strong enough to handle the hardness of metal or the heat generated during the process.

4. Are there any safety concerns when cutting metal?

When cutting metal it is important to wear protective gear such as safety glasses and gloves. Metal shavings can be sharp and may cause injury if proper precautions are not taken.

5. Where should I go for help if I need to cut metal properly?

If you need guidance on how to safely and effectively cut metals, it’s best to consult with experts at hardware stores or seek advice from professionals in industries that involve working with metals like fabrication shops or welding workshops.