In intermediate woodworking, one of the most common cuts I have had to make is the crosscut. There are two ways to execute it, I’ve learned. One requires driving wood across a blade, while the other requires the blade to move across the wood. The method I use to make a crosscut dictates the kind of support/tools I need

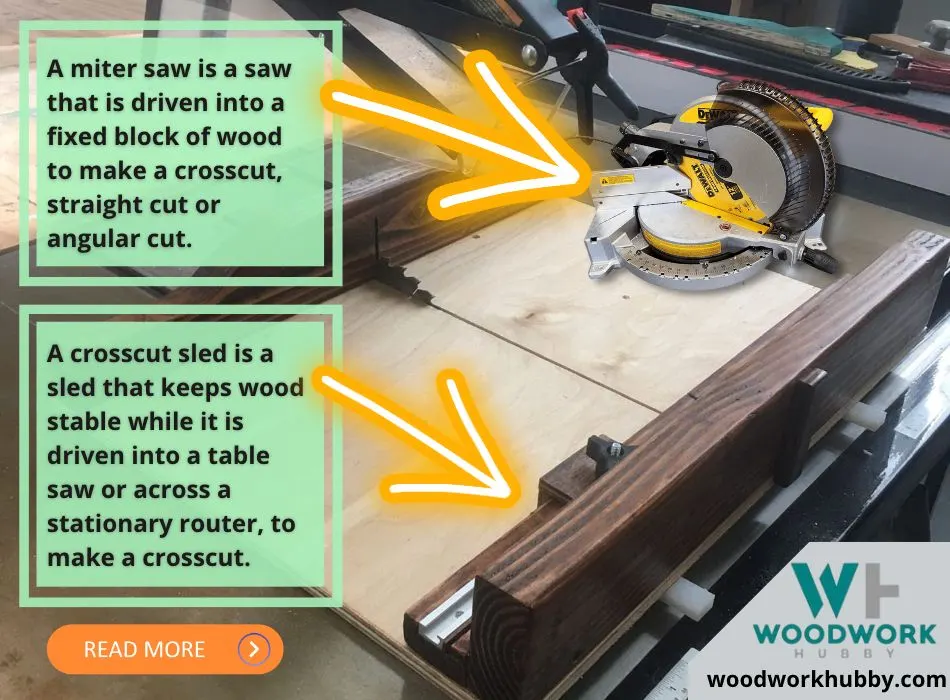

A crosscut sled is a sled that keeps wood stable while it is driven into a table saw or across a stationary router, to make a crosscut. A miter saw is a saw that is driven into a fixed block of wood to make a crosscut, straight cut or angular cut.

Both of the tools have some overlapping uses but are more different than they are similar. In this article, you will find out the key differences between a crosscut sled and a miter saw alongside their respective tasks.

You will learn which one is more versatile and which one you should get or set up if you have two choose between these two.

This post covers videos, tables, and my tips from 20+ years of woodworking experience. So bookmark it before reading further in case you need to refer to it later.

| Aspect | Miter Saw | Crosscut sled |

|---|---|---|

| Cutting angles | Multiple | Single |

| Cut types | Crosscut, straight cut, angular cuts (bevels/miters) | straight cuts and cross cuts |

| Functional value | It is a blade that is driven at a pre-set angle | It is a sled that holds the wood still as it goes toward a blade |

| Acquisition | Can be purchased | Needs to be built |

What Is The Difference Between A Crosscut Sled And A Miter Saw?

A crosscut sled is a support structure that supports both sides of a wood piece during a crosscut made with a table saw. A miter saw is a sawing tool that allows the blade to be plunged into stationary wood to make a crosscut.

Both of these tools are meant to facilitate crosscuts, albeit in different orientations. Which one is better depends on your comfort with the individual item alongside the wood’s compatibility with it? The more mobile a piece of wood, the better it is cut with a crosscut sled, and a table saw. And the heavier the wood, the better it is cut without much movement.

Availability is another important factor to consider. If you don’t have a table saw, then a crosscut sled isn’t as helpful. And if you have a miter saw, you won’t really find a place to attach it to a miter saw.

Availability is another important factor to consider. If you don’t have a table saw, then a crosscut sled isn’t as helpful. And if you have a miter saw, you won’t really find a place to attach it to a miter saw.

Do I Need A Crosscut Sled If I Have A Miter Saw?

If you have a miter saw, you don’t need a crosscut sled. The crosscut sled is a table saw accessory that helps keep wood stable as the wood is moved across an upright blade. Since the miter saw blade is plunged into fixed wood, there is no point in a stable movement tool.

After using many table saws throughout my career, I decided to make a list of the best table saws under $1500. These have either been used personally or by my woodworking peers.

If you have a table saw, then you can decide between getting a crosscut sled, and a miter saw. If you have a miter saw but have not set up, a table saw, constructing a crosscut sled would be pretty pointless. For woodworkers who are setting up their first shop, there are two paths. They can start with a crosscut sled, a table saw, or a miter saw.

My current workshop has plenty of tools that are redundant. But when I started woodworking 20 years ago, I didn’t equip my shop to the teeth. And I would recommend you don’t either. Instead, you should equip your shop with the tools that help you execute the initial projects you are interested in.

My current workshop has plenty of tools that are redundant. But when I started woodworking 20 years ago, I didn’t equip my shop to the teeth. And I would recommend you don’t either. Instead, you should equip your shop with the tools that help you execute the initial projects you are interested in.

The table below shows which tasks can be conducted with the help of these two tools. It will help you identify the ones that are appropriate for you as of now.

| Function | Can a crosscut sled do it? | Can a miter saw do it? |

|---|---|---|

| Angled cuts for molding | No | Yes |

| Trim work | Yes | Yes |

| Straight cuts | Yes | Yes |

| Crosscuts | Yes | Yes |

| Rafters | No | Yes |

| Bevel cuts | No | Occasionally |

As you can see, a miter saw can do pretty much everything a crosscut sled can do, but not everything that some miters can do can be done with a crosscut sled. Then why do miter saws and crosscut sleds get compared?

This confusion occurs because of the miter gauge, which is functionally similar to crosscut sleds. Because it includes the word miter, some woodworkers might confuse it with a miter saw. A miter gauge is an add-on to the table saw, which serves a function similar to that of a crosscut sled.

A miter gauge (not a miter saw) provides support for a moving wood block as it is pushed past a blade. Since this can make a crosscut sled redundant to an extent, you might wonder if crosscut sleds are even required at all.

Is A Crosscut Sled Necessary?

A crosscut sled is necessary for medium-sized woodblocks that are meant to be cut using a table saw. It is not necessary for small wood pieces if you have a miter gauge or for large pieces if you have a miter saw.

Ultimately, it is a straight-holding and stabilizing structure that is useful in maintaining the accuracy of cross-cuts.

If you can use any other contraption or tool to get a straight cut without a crosscut sled, you do not need the sled. The two contexts that make a cross-cut sled useless are: using a mobile miter saw and having a miter gauge.

Can You Use A Miter Gauge As A Crosscut Sled?

A miter gauge can act as a crosscut sled for smaller wood pieces. However, it can ad support from one side only, which means larger wood pieces can become unstable when they meet the resistance of a blade.

Miter gauges also have a short fence problem, which limits the size of wood they can accommodate. Fortunately, you can expand the fence of a miter gauge by adding a wood panel over it.

After attaching an expandable fence and ensuring that the support to the wood piece is uniform from both sides, the final aspect that remains is the angle-setting one. Since miter gauges help adjust wood to different angles before driving it into the blade, they are not always perpendicular. This can introduce inaccuracy in the formation of the cut.

In other words, you can use a miter gauge as a crosscut sled, but its function will be very limited. Some miter gauges are better at crosscut support than others. But overall, larger pieces of wood need more bonafide support, which only a crosscut sled can provide. Fortunately, you can make a crosscut sled fairly easily at home.

The following video shows how you can make a crosscut sled and how it differs from a miter gauge:

A video showing how you can make a crosscut sled and how it differs from a miter gauge.

If you build a crosscut sled or decide that a miter gauge is enough for your woodworking needs, you might not need a miter saw. However, miter saws have functions that these stabilizing tools cannot fulfill, which is why you have to be clear about the type of woodworking projects you want to execute.

Refer to the table included earlier to be sure about whether you need to get a miter saw or build a crosscut sled.

Do You Need A Miter Saw?

You need a miter saw to make angular cuts and cross cuts. If you need to make crosscuts only and have a miter gauge or a crosscut sled to go with your table saw, you do not need a miter saw.

Since a Miter saw is integral to almost all angular cuts, you will need one eventually. But not all woodworkers need miter saws. Plenty of woodworking projects can be executed with only crosscuts and straight cuts, which need nothing more than a table saw and some support for the wood pieces.

Knowing the type of projects you want to make is also important for crosscut sled selection/building. Since you can make a crosscut sled to be as big or as small as you want, knowing the average wood piece size can help you avoid oversizing or under sizing the sled.

You may also want to know if a miter saw can cut a 4×4 by clicking the link provided.

What Size Should A Crosscut Sled Be?

A crosscut sled can be as wide as the saw top allows it to be. As long as it is wide enough to allow clamping at either side of the stops, it will be functional. The sled’s front fence should be at least one inch thick, and its rear fence should be 1.5 inches thick.

I have found a good size for a crosscut sled to be approx. 23″ x 23″ (600 x 600mm)

The thickness of the fence ensures the stability of the wood as it is driven across the blade. If the fence is too thin, it can wear out across multiple cuts. Moreover, it can get bent or may wobble on impact, especially if the blade is blunt.

On the other hand, if a crosscut sled is too small, it can have the same limitations as a miter gauge. And if it is too big, it can become impossible to handle.

Ultimately, the goal of a crosscut sled is to keep wood in place while it is being cut. If the sled is too big to push smoothly across the blade, then it does the opposite of what it is supposed to do.

If you have had a rough start with table saws, anything that promotes smoothness will make you think about kickbacks. You’re not alone because one of the questions I get asked most often is whether a crosscut sled can be used as a way of minimizing kickback.

Does A Crosscut Sled Prevent Kickback?

A crosscut sled can prevent kickback if you don’t use a stop block. But if you use a stop block, the pressure from all sides can launch the wood piece in almost any direction. So, don’t use a stop block and a crosscut sled together, especially if the wood that you’re cutting is too light to stay in place on its own weight.

Tips For The Miter Saw And Crosscut Sleds

With that out of the way, I would like to cover some of the tips I promised earlier on. Since I have used both types of tools, I can give you a few pointers regardless of whether you choose to use a crosscut sled or a miter saw.

In this section, you will learn the aspects worth considering and the things that you should be doing when you use each of these tools.

Crosscut sled best practices:

- Build a crosscut sled that serves you – From the size of the sled to the thickness of the fences, you get to choose what works for you. Don’t build a sled you cannot use.

- Use Johnson’s paste wax to make your crosscut sled slide better – A coat of this wax under the runners can make the sled slide more smoothly.

- Mill the sled runners with the grain to avoid side-to-side expansion – This is crucial since most wood movement is along the grain.

- Build the sled in two parts to be joined later – Any attempt at making a single-unit sled will make it easy to miss the mark with measurements, and the result might not fit the saw top.

- Square the fence to the blade – This is obviously crucial for accurate cuts.

Miter saw best practices:

- Support longer pieces of wood with a stand – Mitre saws aren’t usually built to accommodate long wood pieces, but a stand can help.

- Calibrate and sharpen the blade before using it – Mitre saw calibration has variations. The blade may also get blunt. Both of these can make cuts less smooth.

- Double-check the angle – Since miter saws don’t just cut straight. You might make angular cuts by accident if you don’t fix the angle.

- Wear loose clothing and eye protection – This is for your own safety.

Here is a table showing my recommended products and where to buy them:

Final Thoughts – Crosscut sled vs Miter Saw

When it comes to crosscut sled vs. miter saw, the discussion isn’t about crosscuts but the situation that a woodworker is in. If he has a table saw, then the easiest path to getting a crosscut is by using a miter gauge or building a crosscut sled. If he has a miter saw, then setting up a table saw and crosscut sled is too much work.

You must decide which tool is better for you based on the size of your project and the kind of work you want to undertake. But generally speaking, a crosscut sled is better for medium-sized wood, while a miter saw is better for heavy wood that can fit a miter saw.