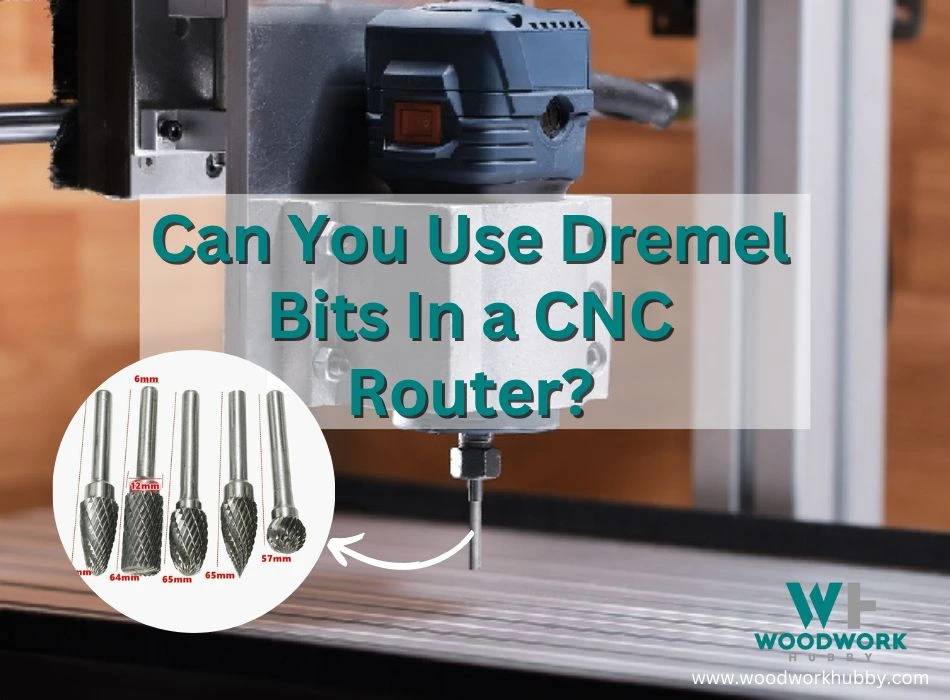

A CNC router is a convenient contraption to finish, sand, round, or drill aspects of your project with no room for error. A computer-driven machine is much better at handling the standard repetitive motions in wood carving and engraving. But what do you do if your CNC router is missing its routing head? Can you use Dremel Bits in a CNC router?

In general, you can use Dremel bits in a CNC router if the CNC is customized to be Dremel-compatible. Most standard CNC routers will have a collet that is too large to accept Dremel bits. Dremel bits will not last long in a CNC due to the higher speeds of a CNC.

In this article, you will learn the different uses of Dremel bits in relation to customized CNC machines and other tools like routers. You will also find out more about using drilling bits with a CNC and things to keep in mind when using Dremel bits with more potent machines.

By the end, you will know how to make use of Dremel accessories and what to add to a CNC. But first, let’s explore the bits’ compatibility with different CNC machines.

Can I Use Dremel Bits In a CNC?

You can use Dremel bits in a CNC, if the device is homemade to use a handheld routing tool. In that case, you can attach most carving appendages to the CNC. Dremel bits are interchangeable with other brands’ rotary tools, and a CNC that features a rotating head can make use of such add-ons. One can also turn a Dremel rotary tool into a CNC.

CNC stands for Computer Numerical Control, which refers to a program that lets computers replace the woodworker to a large extent. A design is fed into a computer attached to a CNC machine, and the program dictates the carving, rotating, and movement of the machine’s shapers. Think of it as 3D printing but for wood.

In 3D printing, the manufacturing appendages release the crafting material in line with the 3D model fed to the printer. With most CNCs, the crafting process is the opposite, where the design fed dictates what the machine will remove from a slab of wood.

As long as the machine reads the commands accurately, it can work with any brand bits.

Did you know how accurate is a CNC? See my full article explaining this.

Different CNCs can have different crafting mechanisms, including a few rare ones that have a chisel with a back-and-forth motion, not unlike a tattoo pen. How well a CNC works with Dremel bits depends on the operating principle of the machine and the Dremel tool.

You cannot use Dremel saw bits on a CNC rotary tool. Similarly, the Dremel rotary head won’t assimilate properly in a CNC saw.

To use Dremel bits in a CNC machine of any sort, the following conditions must be met.

- The function of the Dremel Tool should match the function of the CNC machine – A Dremel saw part will fit in a CNC saw, and a Dremel rotary tool head will fit a CNC routing machine. This principle extends to all CNC machines and their equivalent in Dremel tools.

- The CNC machine should have space for the specific Dremel attachment – A Dremel saw handle might not fit a CNC saw that doesn’t have room for manual handling, but if the machine has space for a blade, the Dremel blade will work. The only time this condition can be ignored is when you are building your own CNC machine.

- The CNC machine should use a standard rotary tool – Industrial CNCs and even mid-range workshop devices feature different-sized bits than Dremel bits. However, Dremel bits can be used with other rotary tools like certain handheld routers. If such a router is attached to a CNC, then the apparatus can make use of Dremel bits.

- The Dremel bit should be available as a separate accessory – When a Dremel bit is separately available, it can often be used with other brands’ equivalent products. For example, Dremel rotary tool bits available for separate purchase can be used with other brands’ rotary tools. The same applies to saws as well as oscillating tools. However, when you remove a Dremel part not available as a separate spare, you may not find room for it in a CNC machine.

Can You Use Dremel Bits in a Router?

You can use Dremel bits in a router if the bits come from a Dremel rotary tool and the shaft size is correct. While Dremel manufactures Saws, oscillating shapers, and rotary tools, its products are not the same as a router. Wherever the working principle of a router and a Dremel converge, you can use parts interchangeably.

CNC’s run at higher speeds than Dremel Tools

so the bits would not last long.

Similarities Between a Dremel And a Router

As mentioned above, the extent to which Dremel bits can be used in a router is dictated entirely by the function of both machines. Only where the moto-tool’s functions overlap with a router can you use Dremel bits in a router.

Both the tools use a fast spinning collect and can be used for polishing, sanding, rounding, and engraving. Within these functions, the Dremel attachments can be used on a router, and the moto-tool itself can also be turned into a router, albeit an inefficient one.

Be sure to check out my full guide on how long do router bits last? You might be surprised!

Dremel’s spinning velocity is far below that of a router. Dremel movement is pedestrian compared to a router. Moreover, a router is far more durable because it is used on sturdier wood for more professional work.

Dremels are often used as gateway tools for DIY projects and by semi-professionals. Here’s what that entails for part-swapping.

Table Saw As A Router? Which is Best? See my full breakdown.

Dremel Bits Used in a Router Will Not Last Long

Given that routing bits are most often used in a router, the Dremel bit will face rigorous friction with a spinning collet far more powerful than that of a Dremel Moto-Tool. As a result, the lifespan of the routing head will be cut short significantly.

The router will be downgraded in function – A router is more powerful than a Dremel, but any machine is as powerful as its least potent functioning bit. When you add a Dremel bit to a router, you can use the router to the same extent as a Dremel, but you cannot raise the functionality of the Dremel bit to that of a router head.

Be sure to read my article explaining how long CNC router bits last?

Your practice will be non-standard – When you use bits from one machine in another, you create a hybrid tool. Hybrid tools are okay to use as long as they give you the results you desire. However, you should not use hybrid machines at the beginning of your journey as you are still learning.

Using a standard router or a regular Dremel should be second nature to you before you can afford to use a hybrid. Otherwise, your baseline routing intuition will be set on a hybrid tool.

Consider running your CNC at much slower speeds!

Can You Use Drill Bits in a CNC?

Dremel bits can serve a range of functions while leveraging the same operating principle. The moto-tool can be used to round, saw, polish, or etch, depending on the head size. While these bits fit perfectly with any tool that uses a motor to spin a surface-standing head, what about Dremel drill bits?

Drill bits can be used in a CNC drill though attaching the drill bit to the CNC machine can be challenging. The CNC and the Dremel drills use the same operating principle, albeit at different spinning velocities. You can change drill heads and routing bits in a multi-function CNC machine.

That said, CNC machines that are made for routing and etching don’t take well to being modified with drill bits. Remember, the bits remain interchangeable across brands and even machine modes as long as their functions overlap.

Under those circumstances, using drill bits is ideal for CNC drills and not CNC routers or CNC engraving machines.

Here are some of the best practices of using drill bits in a CNC drill.

- Operate at optimum operational spin velocity – CNC collets usually have the capacity to spin as slow as a standard Dremel, which is better than router collets.

- When using a Dremel drill bit with a CNC, slow down the spin velocity – If you use a drill bit from a standard drill with higher motor capacity, you might have to increase the CNC’s spin to match.

- Make the drill bit feel at home to avoid over-drilling or making the head blunt.

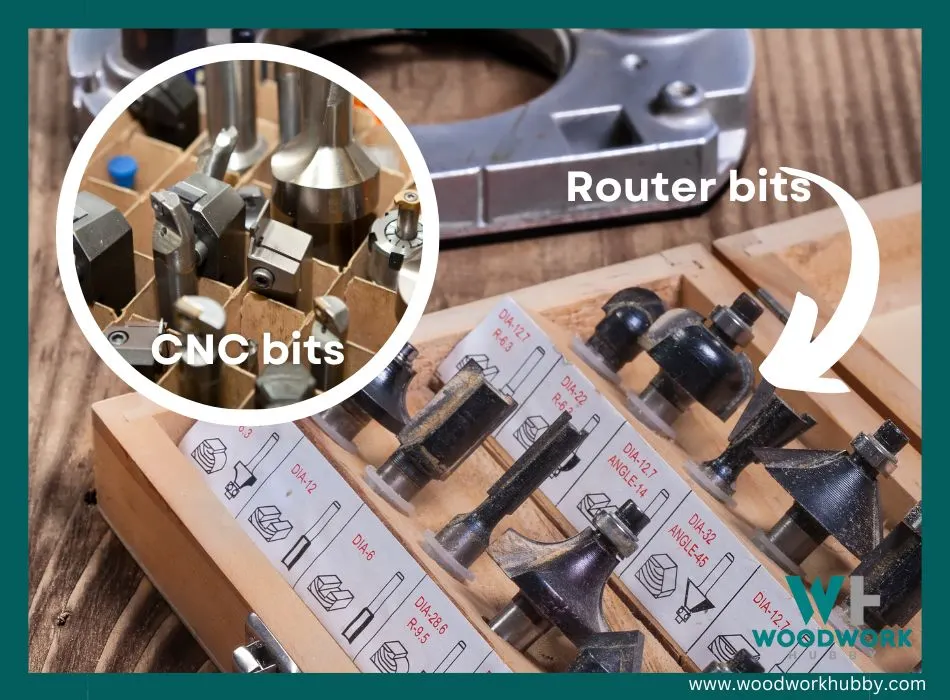

Are CNC Router Bits Different?

Whether you have a Dremel rotary tool or a hand-held router with multiple attachable heads, you might wonder where else the routing bits can be used. Since the operating principle behind most routing devices is the same, they can accomplish all the same things. Most devices that can accommodate multiple heads come with a set of router bits.

CNC router bits are different in size and function. Generally, CNC router bits are designed for higher speeds, cutting, and engraving. While Dremel bits spin much slower and also come in sanding & polishing bits. These bits can be attached to other tools as long as they can be fixed in place of the respective machine’s routing head.

Read further down to learn more about CNC routers and standard router bits and whether they are different or the same. You will find out if you can use them interchangeably, but before that, you must learn the best practices of such swaps.

To make sure your CNC router bits last longer, you must adhere to the following best practices:

- Store away from the elements, avoid exposure to destabilizing factors – If your CNC router bits are not in use, there is no point putting them on the work table. Use proper storage for your CNC router bits so they don’t erode.

- Use router bits with lower velocity motors – Check the spin velocity of your CNC router’s spinning collet. Use the router bits only if a tool has a lower spin velocity than that of your CNC’s collet.

- Do not use on surfaces they aren’t meant for – It helps to learn more about which surfaces the routing bits work on. As a rule of thumb, most natural wood is conducive to etching and engraving with a CNC router. Resellers can sometimes make false claims, so you should check what the original sales page of the CNC says to confirm if the bits can be used on surfaces other than wood.

Are CNC and Router Bits the Same?

CNC is a term that can cover a range of computer-driven routing, drilling, and sawing machines. But generally, CNC is used interchangeably with a CNC router. So when one asks about the similarities between a CNC and router bits, the question is essentially about the difference between a human-held router and a Software-driven router.

CNC and Router bits are different but can be used interchangeably. While the bits used in a Bosch or DeWalt router may not be exactly like the ones that come with a CNC router, they can still function in the CNC machine, which sometimes accommodates installing an entire third-party router.

Final Thoughts – Can You Use Dremel Bits In a CNC Router?

You could use Dremel bits in a CNC if the shaft size is the same and you only use them sparingly. Dremel bits are relatively inexpensive and pretty feasible for small-scale DIY projects.

But if you want to make a portion of your craftwork hand-free, you might want to bring home a CNC. A Computerized Numerical Control unit can route based on the plans fed to the software it is plugged into and can use Dremel bits to do the work you would otherwise use the Dremel moto-tool for.